I-PET

I-polyethylene terephthalate (kwesinye isikhathi kubhaliwe i-poly (ethylene terephthalate)), evame ukufushaniswa I-PET, Pete, noma i-PETP engasebenzi noma i-PET-P, yiyona evame kakhulu i-thermoplastic i-polymer resin of I-polyester Umndeni futhi usetshenziselwa imicu yezingubo, iziqukathi ngoketshezi nokudla, i-thermoforming yokukhiqiza, futhi kuhlangene ne-fiber fiber yama-resin wobunjiniyela.

Kungabhekiswa futhi ngegama lomkhiqizo I-Dacron; eBrithani, Terylene; noma, eRussia kanye ne-Soviet Union yangaphambili, Lavsan.

Iningi lomkhiqizo we-PET womhlaba ungowezintambo zokwenziwa (ezingaphezulu kwama-60%), ngokukhiqizwa kwamabhodlela okubalwa cishe ama-30% wesidingo somhlaba jikelele. Kumongo wezicelo zendwangu, i-PET ibizwa ngegama layo elijwayelekile, I-polyester, kanti isichazamazwi I-PET isetshenziswa ngokuvamile maqondana nokupakisha. IPolyester yakha cishe i-18% yokukhiqizwa kwama-polymer omhlaba futhi ingumkhiqizo wesine okhiqizwa kakhulu i-polymer; i-polyethylene(PE), i-polypropylene (PP) ne i-polyvinyl chloride (PVC) ingeyokuqala, eyesibili neyesithathu ngokulandelana.

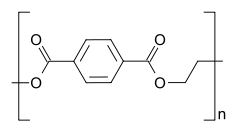

I-PET iqukethe yenziwe ngombala amayunithi we-monomer ethylene terephthalate, ngokuphindaphinda (C10H8O4) amayunithi. I-PET ijwayele ukwenziwa kabusha, futhi inenombolo 1 njengophawu lwayo lokuphinda usebenzise.

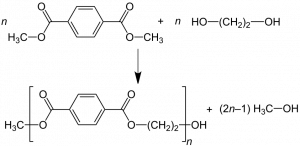

Ngokuya ngomlando wayo wokusebenza nokushisa, i-polyethylene terephthalate ingahle ibe khona njenge-amorphous (esobala) nanjenge i-semi-crystalline polymer. Izinto ze-semicrystalline zingahle zibonakale zisobala (usayizi wezinhlayiyana <500 nm) noma opaque nomhlophe (usayizi wezinhlayiyana ofinyelela kuma-micrometer ambalwa) kuya ngesakhiwo sayo se-crystal nosayizi wezinhlayiyana. I-monomer yayo bis (2-hydroxyethyl) terephthalate ingahlanganiswa ukuqinisekiswa ukusabela phakathi i-terephthalic acid futhi i-ethylene glycol ngamanzi njenge-byproduct, noma nge transesteration ukusabela phakathi i-ethylene glycol futhi i-dimethyl terephthalate nge i-methanol njengemiphumela. I-polymerization ngokusebenzisa i- a polycondroll ukusabela kwama monomers (kwenziwe ngokushesha emva kokuhlukaniswa / ukufakelwa) ngamanzi njengokuphuma komgwaqo.

| Amagama | |

|---|---|

| Igama le-IUPAC

I-Poly (ethyl benzene-1,4-dicarboxylate)

|

|

| Izikhombi | |

| 25038-59-9 |

|

| Izifinyezo | PET, PETE |

| Izakhiwo | |

| (C10H8O4)n | |

| Isisindo seMolar | okuguquguqukayo |

| Ubuningi | 1.38 g / cm3 (20 ° C), i-amorphous: 1.370 g / cm3, i-crystal eyodwa: 1.455 g / cm3 |

| Iphuzu lokuxuba | > 250 ° C, 260 ° C |

| Iphuzu lokubilisa | > 350 ° C (iyabola) |

| cishe ayisebenzi | |

| Ukuqhuba kwe-thermal | 0.15 kuya ku-0.24 W m-1 K-1 |

| 1.57-1.58, 1.5750 | |

| I-Thermochemistry | |

| I-1.0 kJ / (kg · K) | |

| Amakhompiyutha ahlobene | |

|

Izinsiza Ezinhlobene Ama-Monomers

|

I-Terephthalic acid I-Ethylene glycol |

|

Ngaphandle kwalapho kubhalwe ngenye indlela, imininingwane inikezwa ngezinto zokwakha isimo esijwayelekile (ngo-25 ° C [77 ° F], 100 kPa).

|

|

Usetshenziswa

Ngoba i-PET iyinto enhle kakhulu yokuvinjwa kwamanzi nomswakama, amabhodlela epulasitiki enziwe nge-PET asetshenziswa kabanzi kwiziphuzo ezithambile (bona i-carbonation). Ngamabhodlela athile akhethekile, njengalawo aqokelwe isithako sobhiya, i-PET isandwich isendlalelo esingeziwe se-polyvinyl (PVOH) ukuqhubekisela phambili ukuncipha kwemvume ye-oxygen.

I-PET ethambekele enkingeni ifilimu (evame ukwaziwa ngelinye lamagama ayo okuhweba, "Mylar") ingakhanyiswa ngokuhwamuka ifilimu lensimbi elincanyana kuyo ukuze inciphise ukungena kwayo, futhi iyenze ibukeke futhi ibukeke (I-MPET). Lezi zakhiwo ziwusizo ezinhlelweni eziningi, kufaka phakathi nokudla okuguqukayo emaphaketheni futhi ukufakwa okushisayo. Bona: "izikhala zokulala“. Ngenxa yamandla ayo aphezulu wokukhanda, ifilimu ye-PET ivame ukusetshenziswa ezinhlelweni zeteyipu, njengothwala iteyipu kazibuthe noma ukusekelwa kwamateyipu wokunamathela azwelayo.

Ishidi le-PET elingagxiliwe lingaba ukushisa ukwenza amaphakethe okupakisha nama-blister pack. Uma kusetshenziswa i-crystallizable PET, ama-tray angakwazi ukusetshenziselwa ukudla okudliwayo okuyiqhwa, ngoba amelana nokushisa kwamahhala kanye nokushisa kuhhavini. Ngokuphikisana ne-PET ye-amorphous, ebonakalayo, i-PET ekhanyayo noma i-CPET ibonakala imnyama ngombala.

Lapho igcwaliswa ngezinhlayiya zeglasi noma imicu, iba lukhuni futhi ihlala isikhathi eside.

I-PET isetshenziswa futhi njengengxenye yeseli kumaseli amancane elanga lamafilimu.

I-Terylene iphinde ifakwe ezingxenyeni zezintambo zensimbi ukusiza ukuvikela ukugqokwa ezintanjeni njengoba bedlula ophahleni.

Umlando

I-PET yayinelungelo lobunikazi ngo-1941 nguJohn Rex Whinfield, uJames Tennant Dickson kanye nomqashi wabo iCalico Printers 'Association of Manchester, England. I-EI DuPont de Nemours eDelaware, eU.SA, yaqala ukusebenzisa uphawu lokuhweba iMylar ngoJuni 1951 futhi yathola ukubhaliswa kwayo ngo-1952. Kuseyigama elaziwa kakhulu elisetshenziselwa ifilimu le-polyester. Umnikazi wamanje wophawu lokuhweba yiDuPont Teijin Films US, ubambiswano nenkampani yaseJapan.

ESoviet Union, i-PET yaqala ukwenziwa emalabhorethri e-Institute of High-Molecular Compounds e-USSR Academy of Sciences ngo-1949, futhi igama layo elithi "Lavsan" yisifinyezo salo (laборатории Института высокомолекулярных соединений Ака н…

Ibhodlela le-PET lalinelungelo lobunikazi ngonyaka we-1973 nguNathaniel Wyeth.

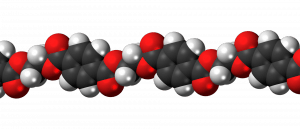

Izakhiwo zomzimba

I-PET esimweni sayo semvelo iyi-resin engenambala, eyi-semi-crystalline. Ngokuya ngokuthi kusetshenzwa kanjani, iPET ingaba lukhuni ngokuqinile, futhi ilula kakhulu. Kwenza umgoqo omuhle wegesi nomswakama olungile, kanye nesithiyo esihle otshwaleni (kudinga ukwelashwa okwengeziwe "kwesithiyo") kanye nezixazululo. Inamandla futhi ayimelani nomthelela. I-PET iba mhlophe lapho ivezwa yi-chloroform kanye namanye amakhemikhali afana ne-toluene.

Cishe i-60% i-crystallization ingumkhawulo ophezulu wemikhiqizo yezentengiso, ngaphandle kwe-polyester fibers. Imikhiqizo ecacile ingakhiqizwa ngokushesha okupholile kwe-polymer engaphansi kwe-Tg ingilazi lokushisa lokuguqula ukwakha okuqinile kwe-amorphous. Njengengilazi, amafomu e-amorphous PET akha lapho ama-molecule awo enganikezwa isikhathi esanele sokuzihlela ngendlela ehlelekile, yekristalu njengoba ukuncibilika kupholile. Ekamelweni lokushisa ama-molecule afriziwe endaweni, kepha, uma amandla okushisa anele abuyiselwa kuwo ngokushisa ngaphezulu kwe-Tg, ziqala ukuhamba futhi, zivumela amakristalu ukuba aqine futhi akhule. Le nqubo yaziwa ngokuthi i-state-state crystallization.

Lapho ivunyelwa ukupholisa kancane, ipolymer encibilikisiwe yakha into ekhala ngaphezulu. Lokhu okubalulekile kunakho ama-spherulites equkethe eziningi ezincane amakristalu lapho ikristallallized kusuka ku-amorphous solid, esikhundleni sokwenza i-crystal eyodwa enkulu. Ukukhanya kuvame ukusaba njengoba kweqa imingcele phakathi kwama-crystallites kanye nezifunda ezi-amorphous phakathi kwazo. Lokhu kusakazeka kusho ukuthi i-crystalline PET yi-opaque futhi imhlophe ezimweni eziningi. Umdwebo wefiber uphakathi kwezinqubo ezimbalwa zezimboni ezikhiqiza umkhiqizo ocishe ufane nowekristalu.

Ukubonakala okungaphakathi

Enye yezimpawu ezibaluleke kakhulu ze-PET kubhekiselwa kuzo njenge ukubukeka okungaphakathi (IV).

Ukubonakala okungaphakathi kokuqukethwe, okutholakala ngokufaka kungaphezulu kokuqina okungu-zero kokuzwakalayo okuhlobene kokukalwa okulinganiswa ama-deciliters ngegramu (dℓ / g). Ukubonakala okungaphakathi kwe-intrinsic kuncike kubude bamaketanga ayo we-polymer kepha akunawo amayunithi ngenxa yokufakwa ngaphezulu kwe-zero okuhlushwa. Isikhathi eside i-polymer ibopha okungaphakathi kokufakwa kwamaketanga ngakho-ke kuyanda ukuphakama. Ubude obuphakathi beketheni elithile le-resin bungalawulwa ngesikhathi polycondroll.

Ububanzi bokubonakalayo bokubonisa kwe-PET:

Ibanga le-Fibre

- Textile 0.40-0.70

- 0.72-0.98 Ubuchwepheshe, intambo yesondo

Ibanga lefilimu

- 0.60-0.70 I-BoPET (ifilimu ye-PET ethambekele enkingeni)

- 0.70-1.00 Ibanga le-Sheet i-thermoforming

Ibanga lebhodlela

- 0.70-0.78 Amabhodlela Amanzi (isicaba)

- 0.78-0.85 Ibanga lesiphuzo esithambile se-Carbonated

I-Monofilament, ipulasitiki yobunjiniyela

- 1.00-2.00

Ukumisa

I-PET i-hygroscopic, okusho ukuthi imunca amanzi asendaweni ezungezile. Kodwa-ke, lapho le PET "emanzi" isishiswa, amanzi i-hydrolyzes i-PET, inciphisa ukuqina kwayo. Ngakho-ke, ngaphambi kokuba i-resin icutshungulwe emshinini wokubumba, kufanele womiswe. Ukomisa kutholakala ngokusebenzisa a Desiccant noma okomisa ngaphambi kokuthi i-PET ifakwe kumishini yokusebenza.

Ngaphakathi kwesomisi, umoya oshisayo owomile ufakwa phansi kwe-hopper equkethe i-resin ukuze igeleze phakathi kwamaphilisi, isuse umswakama osendleleni. Umoya oshisayo omanzi ushiya phezulu kwe-hopper futhi uqala ugijinywe ngemuva kokuphola, ngoba kulula ukususa umswakama emoyeni obandayo kunomoya oshisayo. Umoya opholile opholile ovele ube usudluliswa embhedeni we-desiccant. Ekugcineni, umoya opholile owomile oshiya umbhede we-desiccant uyashiswa kabusha ngenqubo yokushisa bese ubuyiselwa emuva ngezinqubo ezifanayo ku-loop evaliwe. Imvamisa, amazinga okuswakama asalayo ku-resin kufanele abe ngaphansi kwezingxenye ezingama-50 ngesigidi (izingxenye zamanzi ezingxenyeni eziyinkulungwane zenhlaka, ngesisindo) ngaphambi kokucutshungulwa. Isikhathi sokuhlala esomile akumele sibe sifushane kunamahora amane. Lokhu kungenxa yokuthi ukomiswa kwento engaphansi kwamahora amane kungadinga izinga lokushisa elingaphezu kuka-4 ° C, kulelo zinga i-hydrolysis zingaqala ngaphakathi kwamapellethi ngaphambi kokuba zome.

I-PET nayo ingomiswa ezindaweni ezomile zoma airin resin. Izicishisi zomoya ezicindezelwe azisebenzisi futhi umoya owomile. Umoya omile, ofudumele ocindezelwe usatshalaliswa kumaphayini we-PET njengasesomeni esomile, bese ekhishwa esibhakabhakeni.

Ama-Copolymers

Ngaphezu kokumsulwa (owasekhaya) I-PET, i-PET modified by Copolymerization iyatholakala futhi.

Kwezinye izimo, izakhiwo eziguquliwe ze-Copolymer zifiseleka kakhulu kwisicelo esithile. Ngokwesibonelo, I-cyclohexane dimethanol (CHDM) ingangezwa emgogodleni we-polymer esikhundleni se i-ethylene glycol. Njengoba leli bhulokhi likhulu kakhulu (ama-athomu e-carbon ayisithupha) kuneyunithi ye-ethylene glycol eliyishintshayo, alihambelani namaketanga angomakhelwane ngendlela i-ethylene glycol unit ebingangena ngayo. Lokhu kuphazamisa ukwenziwa kwe-crystallization futhi kwehlisa ukushisa okuncibilikayo kwepolymer. Ngokuvamile, i-PET enjalo yaziwa ngokuthi yi-PETG noma i-PET-G (Polyethylene terephthalate glycol-modified; Eastman Chemical, SK Chemicals, ne-Artenius Italia bangabakhiqizi be-PETG). I-PETG iyi-thermoplastic ecacile ye-amorphous engabunjwa ngomjovo noma ishidi likhishwe. Ingafakwa umbala ngenkathi kusetshenzwa.

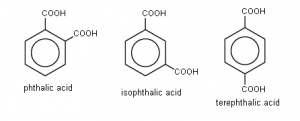

Okunye ukuguquguquka okujwayelekile i-isophthalic acid, kufakwe okunye kwe-1,4- (isigaba-) exhunyiwe umagabade amayunithi. The 1,2- (i-ortho-) noma 1,3- (meta-) Ukuxhumana kukhiqiza i-engele ngeketeni, nakho okuphazamisa i-crystallinity.

Ama-Copolymers anjalo anenzuzo ezinhlelweni ezithile zokubumba, ezifana i-thermoforming, osetshenziselwa ukwenza isibonelo se-tray noma i-blister packaging kusuka ku-co-PET film, noma ishidi le-amorphous PET (A-PET) noma ishidi le-PETG. Ngakolunye uhlangothi, i-crystallization ibalulekile kwezinye izinhlelo lapho ukuzinza kwemishini nobukhulu kubalulekile, njengamabhande esihlalo. Emabhodleleni we-PET, ukusetshenziswa kwamanani amancane we-isophthalic acid, CHDM, i-diethylene glycol (I-DEG) noma amanye ama-comonomers angaba usizo: uma kusetshenziswa amanani amancane kuphela we-comonomers, ama-crystallization ancishisiwe kodwa angavinjwanga ngokuphelele. Ngenxa yalokhu, amabhodlela atholakala nge welula blowing isikhunta (“SBM”), okucacile futhi okuyi-crystalline ngokwanele ukuba kube isithiyo esanele emaphunga nakumagesi, njenge-carbon dioxide kuziphuzo ezinekhabhoni.

Production

I-polyethylene terephthalate ikhiqizwa kusuka i-ethylene glycol futhi i-dimethyl terephthalate (C6H4(CO2CH3)2) noma i-terephthalic acid.

Owayekade engu-a transesteration ukusabela, kanti lokhu kokugcina kuyinto ukuqinisekiswa ukusabela.

Inqubo ye-Dimethyl terephthalate

In i-dimethyl terephthalate inqubo, le nhlanganisela ne-ethylene glycol eyedlulele iyasuswa ekuncibilikeni ngo-150-200 ° C nge isikhuthazi esiyisisekelo. I-Methanol (CH3OH) isuswa nge-distillation ukuqhuba ukusabela phambili. I-ethylene glycol eyeqile ikhishwe ekushiseni okuphezulu ngosizo lwe-vacuum. Isinyathelo sesibili se-transesterification sivela ku-270-280 ° C, ne-distillation eqhubekayo ye-ethylene glycol nayo.

Ukuphendula kwalungiswa kanjena:

- Isinyathelo sokuqala

- C6H4(CO2CH3)2 + 2 INDLELA2CH2OH → C6H4(CO2CH2CH2OH)2 + 2 CH3OH

- Isinyathelo sesibili

- n C6H4(CO2CH2CH2OH)2 → [(CO) C6H4(CO2CH2CH2O)]n + n Hoch2CH2OH

Inqubo ye-Terephthalic acid

In the i-terephthalic acid inqubo, ukuhlukaniswa kwe-ethylene glycol ne-terephthalic acid kwenziwa ngqo ekucindezelweni okulingene (ibha ye-2.7-5.5) kanye nokushisa okuphezulu (220-260 ° C). Amanzi aqedwa ekuphenduleni, futhi asuswa ngokuqhubekayo nge-distillation:

- n C6H4(CO2H)2 + n Hoch2CH2OH → [(CO) C6H4(CO2CH2CH2O)]n 2 +n H2O

Ukuqothuka

I-PET ifakwa ezinhlotsheni ezahlukahlukene zokuwohloka ngenkathi kucutshungulwa. Ukuwohloka okuyinhloko okungenzeka kungama-hydrolytic, futhi mhlawumbe okubaluleke kakhulu, i-oxidation esebenzayo. Lapho i-PET yehlisa isithunzi, kwenzeka izinto eziningana: discoloration, chain ukukhipha okuholela ekunciphiseni isisindo samangqamuzana, ukwakheka kwe i-acetaldehyde, Futhi izixhumanisi zesiphambano (Ukwakheka kwe- “gel” noma “fish-eye”). Ukuqhekeka kombala kungenxa yokwakhiwa kwezinhlelo ezahlukahlukene ze-chromophoric kulandela ukwelashwa okude isikhathi eside emazingeni okushisa aphakeme. Lokhu kuba yinkinga lapho izidingo ezibonakalayo ze-polymer ziphakeme kakhulu, njengasezinsizeni zokupakisha. Ukuwohloka okushisayo nokushisayo kwe-thermooxidative kubangela ukungasebenzi kahle kwezici nokusebenza kwendaba.

Enye indlela yokudambisa lokhu ukusebenzisa a Copolymer. Ama-Comonomers afana ne-CHDM noma i-isophthalic acid yehlisa izinga lokushisa elincibilikayo bese unciphise izinga lekristallthi ye-PET (okubaluleke kakhulu lapho kusetshenziswa impahla ekwakheni amabhodlela). Ngakho-ke, i-resin ingakhiwa ngeplastiki emazingeni okushisa aphansi kanye / noma ngamandla aphansi. Lokhu kusiza ukuvimbela ukonakala, kunciphisa okuqukethwe kwe-acetaldehyde komkhiqizo oqediwe kufinyelele ezingeni elamukelekayo (okungukuthi, elingenakuphikwa). Bona Copolymers, ngaphezulu. Enye indlela yokuthuthukisa ukuqina kwepolymer ukusebenzisa izinyibilikisi, ikakhulukazi ama-antioxidants anjenge ama-phosphites. Muva nje, ukuqiniswa kwamazinga wamangqamuzana okusetshenziswa kwamakhemikhali angena nanamuhla nakho sekubhekiwe.

I-Acetaldehyde

I-Acetaldehyde kuyinto engenambala, eguquguqukayo enephunga lezithelo. Yize yakha ngokwemvelo kwesinye isithelo, ingadala ukunambitheka okungekho emanzini asemabhodleleni. Amafomu e-Acetaldehyde ngokucekela phansi i-PET ngokusebenzisa ukuphatha kabi impahla. Amazinga okushisa aphezulu (i-PET ibola ngaphezu kwama-300 ° C noma ama-570 ° F), izingcindezi eziphakeme, isivinini se-extruder (ukugeleza ngokweqile kukhuphula izinga lokushisa), nezikhathi zokuhlala imigqomo emide konke kunomthelela ekukhiqizeni i-acetaldehyde. Lapho kukhiqizwa i-acetaldehyde, eminye yayo ihlala incibilika ezindongeni zesitsha bese kwenza kumkhiqizo ogcinwe ngaphakathi, kuguqulwa ukunambitheka nephunga. Le akuyona inkinga enjalo kwizinto ezingadli (njenge-shampoo), iziphuzo zezithelo (esevele zinalo i-acetaldehyde), noma iziphuzo ezinambitha ezinamandla njengeziphuzo ezithambile. Okomanzi asemabhodleleni, noma kunjalo, okuqukethwe kwe-acetaldehyde okuphansi kubaluleke kakhulu, ngoba, uma kungekho lutho olufaka iphunga, ukugxila okuphansi impela (izingxenye eziyi-10 - 20 ngebhiliyoni emanzini) we-acetaldehyde kungaveza ukunambitheka.

Antimony

Antimony (Sb) kuyinto ye-ironloid esetshenziswa njengento ephulukisa ngesimo samakhompiyutha anjenge i-antimony trioxide (Sb2O3) noma i-antimony triacetate ekukhiqizweni kwe-PET. Ngemuva kokukhiqiza, inani elibonakalayo lokuqagela lingatholakala ngaphezulu komkhiqizo. Lokhu okusele kungasuswa ngokugeza. I-antimony nayo ihlala kokuqukethwe uqobo futhi, ngenxa yalokho, ingahamba iye ekudleni neziphuzo. Ukudalula i-PET ekubandeni noma ekujuleni kokukhula kungakhuphula amazinga we-antimony kakhulu, okungenzeka ngaphezulu kwamazinga wokungcola aphezulu we-USEPA. Umkhawulo wamanzi okuphuza ahlolwe yi-WHO uyizingxenye ezingama-20 ngezigidigidi (i-WHO, 2003), kanti umkhawulo wamanzi okuphuza e-USA uyizingxenye eziyisithupha esigidini ngasinye. Yize i-antimony trioxide inobuthi obuphansi uma ithathwa ngomlomo, ubukhona bayo busakhathaza. AbaseSwitzerland Ihhovisi Lombuso Lezempilo Yomphakathi uphenye inani lokufuduka kwe-antimony, eqhathanisa amanzi afakwe ebhodleleni ku-PET nasengilazini: Ukugxilwa kwe-antimony kwamanzi kumabhodlela e-PET kwakuphakeme, kepha kusengaphansi kakhulu kokuhlushwa okuphezulu okuvunyelwe. I-Swiss Federal Office of Public Health yaphetha ngokuthi amanani amancane e-antimony ayasuka ku-PET aye emanzini asemabhodleleni, kodwa ukuthi ingozi yezempilo yokugxila okuncane okuholelekile ayinakwa (1% of "ukubekezelela ukudla nsuku zonke”Kunqunywa yi- WHO). Ucwaningo lwakamuva (luka-2006) kodwa olusakazwa kabanzi lwathola inani elifanayo le-antimony emanzini kumabhodlela e-PET. I-WHO ishicilele ukuhlolwa kobungozi be-antimony emanzini okuphuza.

Ijusi yezithelo igxila (lapho kungekho mikhombandlela esungulelwe khona), kepha, okwakhiqizwa kwafakwa amabhodlela ePET e-UK kwatholakala ukuthi kuqukethe kuze kufike ku-44.7 µg / L we-antimony, ngaphezu kwemikhawulo ye-EU amanzi ompompi ka-5 µg / L.

I-Biodegradation

UNocardia ingahlazisa i-PET nge-enzyme ye-esterase.

Ososayensi baseJapan bayihlukanise i-bacterium U-Ideonella sakaiensis equkethe ama-enzyme amabili angadiliza i-PET ibe izingcezu ezincane i-bacterium engayigaya. Ikholomu ye I. sakaensis ingahlakaza ifilimu lepulasitiki esikhathini esingamasonto ayisithupha.

Ukuphepha

Ukuphawula kushicilelwe ku- Impilo Yemvelo ngo-Ephreli 2010 iphakamise ukuthi i-PET ingahle ithele abaphazamisi be-endocrine ngaphansi kwezimo zokusetshenziswa okujwayelekile nokucwaningwayo okunconyiwe ngalesi sihloko. Izinqubo eziphakanyisiwe zifaka ukulethwa kwe phthalates kanye nokufundiswa kwe ubutha. Isindatshana esishicilelwe ku Ijenali yokuqapha Imvelo ngo-Ephreli 2012 uphetha ngokuthi ukuhlushwa kwama-antimony ku amanzi enzelwe okugcinwe emabhodleleni e-PET kuhlala ngaphakathi komkhawulo owamukelekayo we-EU noma ngabe kugcinwe isikhashana emazingeni okushisa aze afike ku-60 ° C (140 ° F), ngenkathi okuqukethwe okusemabhodleleni (amanzi noma iziphuzo ezibandayo) kwesinye isikhathi kungadlula umkhawulo we-EU ngemuva kokugcina isikhathi esingaphansi konyaka izinga lokushisa.

Imishini yokulungisa amabhodlela

Kunezindlela ezimbili eziyisisekelo zokubumba zamabhodlela we-PET, isinyathelo esisodwa nesinyathelo ezimbili. Ekubunjweni kwezinyathelo ezimbili, kusetshenziswa imishini emibili ehlukene. Umjovo womshini wokuqala ubumba i-preform, efana ne-tube yokuhlola, lapho imicu yebhodlela cap isivele ibunjwe endaweni yayo. Umzimba we-tube mkhulu ngokuba mkhulu, ngoba uzokhushulelwa esimweni sokugcina esinyathelweni sesibili usebenzisa welula blowing isikhunta.

Esinyathelweni sesibili, izinto ezisetshenziswayo kuqala ukufuthelana ngokushesha bese ziphuphuma amandla okubumba okubumba okuvela ezingxenyeni ezimbili ukuze zikwazi ukwakheka ekugcineni kwebhodlela. Ama-Preforms (amabhodlela angafakwanga) manje asetshenziswa futhi njengezitsha eziqinile nezingafani ngokwazo; ngaphandle kwamaswidi amasha, ezinye izahluko zeRed Cross zibasabalalisa njengengxenye yohlelo lweVial of Life kubanini bamakhaya ukugcina umlando wezokwelapha kwabaphenduli abezimo eziphuthumayo. Okunye ukusetshenziswa okuvame kakhulu kwelempuleli yiziqukathi zomsebenzi we-Geocaching ongaphandle.

Kumishini yesinyathelo esisodwa, yonke inqubo kusuka ezintweni ezingavuthiwe iye esitsheni esiqediwe yenziwa ngaphakathi komshini owodwa, ikwenza kufaneleke kakhulu ekubumbeni amajamo angewona ajwayelekile (isikhunta sangokwezifiso), kufaka phakathi izimbiza, okusaqanda okuyisicaba, imilobo yembobo nokunye. ukuncishiswa kwendawo, ukuphathwa komkhiqizo namandla, kanye nekhwalithi yokubuka ephakeme kakhulu kunokuthi kutholwe ngohlelo lwezinyathelo ezimbili.

Imboni yokuphinda isebenze kabusha

Ngonyaka we-2016, kwakulinganiselwa ukuthi kukhiqizwa amathani ayizigidi ezingama-56 ePET unyaka ngamunye.

Ngenkathi iningi le-thermoplastics lingakwazi, ukusebenza kabusha, Ukuvuselelwa kwebhodlela le-PET isebenza kakhulu kunezinye izinhlelo eziningi zepulasitiki ngenxa yenani eliphakeme le-resin kanye nokusetshenziswa okucishe kube okukhethekile kwe-PET yamanzi asetshenziswa kabanzi nebhodlela elithambile lesiphuzo. I-PET inayo khombisa ikhodi we-1. Ukusetshenziswa okuyinhloko kwe-PET esetshenzisiwe kabusha yi-polyester fiber, imichilo, neziqukathi ezingezona zokudla.

Ngenxa yokuthi kabusha kwe-PET kanye nokuchichima okuhlobene imfucuza esetshenziswa ngabathengi ngesimo samabhodlela, i-PET ithola isabelo semakethe ngokushesha njengefreyimu ekhaphethi. Izimboni zeMohawk ikhishwe njalo ngo-1999 ngo-100, i-fiber ye-PET ye-17% esetshenziswe kabusha yabathengi Kusukela ngalesosikhathi, amabhodlela angaphezu kwezigidi eziyizinkulungwane eziyi-XNUMX asebuye asebenze kabusha ku-fiber carpet. U-Pharr Yarns, umphakeli wabakhiqizi abanekhaphethi abaningi kufaka phakathi iLooptex, iDobbs Mills, neBerkshire Flooring, khiqiza i-BCF (inqwaba eqhubekayo yokugcwalisa) i-PET ekhaphethi equkethe okungenani okuqukethwe okungama-25% okusetshenziselwe kabusha umthengi.

I-PET, njengamapulasitiki amaningi, futhi iyisikhundla esihle kakhulu sokulahlwa okunamandla (ukubethelwa), njengoba yakhiwa yikhabhoni, i-hydrogen ne-oksijini, enamanani okulandela umkhondo wezinto eziyisiqalo (kepha akunasibabule). I-PET inokuqukethwe kwamandla ngamalahle athambile.

Lapho ukuvuselela kabusha i-polyethylene terephthalate noma i-PET noma i-polyester, izindlela ezimbili ezijwayelekile kufanele zisehlukaniswe:

- Ukuvuselelwa kwamakhemikhali kubuyela emuva ezintweni zokuhlanza zokuqala ezihlanziwe i-terephthalic acid (PTA) noma i-dimethyl terephthalate (DMT) ne i-ethylene glycol (EG) lapho isakhiwo se-polymer sichithwa ngokuphelele, noma sisebenza phakathi bis (2-hydroxyethyl) terephthalate

- Ukuphinda usebenzise kabusha lapho izakhiwo zepolymer yangempela zigcinwa noma ziphinde zenziwe kabusha.

Ukuphinda kusetshenziswwe kabusha kwamakhemikhali kwe-PET kuzobiza izindleko kuphela kusetshenziswa imigqa ephezulu yokuphinda isebenze ngaphezulu kwamathani angaphezu kuka-50,000 2000 / ngonyaka. Imigqa enjalo ibonakala kuphela, uma ngabe, ngaphakathi kwezindawo zokukhiqiza zabakhiqizi abakhulu kakhulu be-polyester. Imizamo eminingana yobukhulu bezimboni yokusungula izitshalo ezinjena zokuphinda zenziwe kabusha zamakhemikhali zenziwe phambilini kodwa ngaphandle kwempumelelo ebuyayo. Ngisho nokuvuselelwa kwamakhemikhali okuthembisayo eJapan akukaze kube yimpumelelo yezimboni kuze kube manje. Izizathu ezimbili zalokhu yilezi: ekuqaleni, ubunzima bamabhodlela wokungcola angaguquki futhi aqhubekayo wokukhipha inani elikhulu endaweni eyodwa eyodwa, futhi, ngokwesibili, amanani akhuphuka ngokuqinile kanye nokuqina kwentengo kwamabhodlela aqoqiwe. Amanani wamabhodlela agayiwe akhuphuka ngokwesibonelo phakathi kweminyaka engu-2008 no-50 asuka cishe ku-500 Euro / ton to more than 2008 Euro / ton in XNUMX.

Ukuphinda kusetshenziswe kabusha ngemishini noma ukusakazwa okuqondile kwe-PET esifundeni se-polymeric kusetshenziswa ngokuhlukahluka okuningi namuhla. Lezi zinhlobo zezinqubo zivamile embonini emincane naphakathi nendawo. Ukusebenza kwezindleko kungenzeka kutholakala ngamakhono wezitshalo eziphakathi kwamathani ayi-5000-20,000 / ngonyaka. Kulokhu, cishe zonke izinhlobo zokubuyiselwa kwezinto ezibonakalayo ezisetshenziswayo ekusakazweni kwezinto ezibonakalayo kungenzeka namuhla. Lezi zinqubo ezahlukahlukene zokuphinda zenziwe kabusha ziyaxoxwa ngokuningiliziwe.

Ngaphandle kwamakhemikhali angcolisayo futhi ukwehlisa imikhiqizo eyenziwe ngesikhathi sokusebenza kokuqala nokusetshenziswa, ukungcola kwemishini kumelela ingxenye esemqoka yekhwalithi yokunciphisa ukungcola ekusakazweni kokusebenziseka kabusha. Izinto ezisetshenzisiwe kabusha zisanda kungeniswa ezinqubweni zokwenziwa, ekuqaleni ezazenzelwe izinto ezintsha kuphela. Ngakho-ke, ukuhlunga okusebenzayo, izinqubo zokuhlukanisa kanye nezokuhlanza zibaluleke kakhulu kumakholishi asezingeni eliphakeme asetshenziswe kabusha.

Lapho sikhuluma ngomkhakha wokuphinda usebenzise kabusha i-polyester, sigxila kakhulu ekuvuseleleni kabusha amabhodlela e-PET, okuyimanje asetshenziselwa zonke izinhlobo zokufakelwa uketshezi njengamanzi, iziphuzo ezithambile zekhabhoni, ujusi, ubhiya, amasoso, okokuhlanza, amakhemikhali wasendlini nokunye. Amabhodlela kulula ukuwahlukanisa ngenxa yokwakheka nokungaguquguquki futhi ahlukaniswe nemfucumfucu epulasitiki kungaba nge-othomathikhi noma yenqubo yokuhlunga ngesandla. Umkhakha osungulwe wokuphinda usebenzise i-polyester uqukethe izingxenye ezintathu ezinkulu:

- Ukuqoqwa kwamabhodlela we-PET kanye nokwehlukaniswa kwemfucuza: izinto zokungcola

- Ukukhiqizwa kwamabhodlela ahlanzekile emabhodlela: ukukhiqizwa kwe-flake

- Ukuguqulwa kwama-PET amaflethi kumikhiqizo yokugcina: ukucutshungulwa kwe-flake

Umkhiqizo ophakathi nendawo ovela kusigaba sokuqala ungcoliso lwamabhodlela ahlanganisiwe anokuqukethwe kwe-PET okungaphezulu kwama-90%. Ifomu lokuhweba elivame kakhulu yi-bale kodwa futhi elikhubazekile noma ngisho elixegayo, amabhodlela anqunywe ngaphambili ayinto evamile emakethe. Esigabeni sesibili, amabhodlela aqoqiwe aguqulwa ahlanzeke amachashaza ebhodlela e-PET. Lesi sinyathelo singaba nzima noma sinciphise futhi sibe yinkimbinkimbi ngokuya ngekhwalithi yokugcina ye-flake. Ngesikhathi sesinyathelo sesithathu, kusetshenziswe amabhodlela e-PET amabhodlela, kunoma yiluphi uhlobo lwemikhiqizo efana nefilimu, amabhodlela, umucu, umucu, imichilo noma imaphakathi njengamapellethi okuqhubekisela phambili kanye nobunjiniyela bamapulasitiki.

Ngaphandle kwalokhu kusetshenziselwa kabusha kwe-polyester ye-bhodlela yangaphandle, izinombolo zezinqubo zokuphinda zenziwe kabusha (zangaphambi komthengi), lapho izinto zokufunda ezingaphili ziphuma endaweni yokukhiqiza ziye emakethe yamahhala, futhi esikhundleni salokho ziphinde zisetshenziswe kumjikelezo owodwa wokukhiqiza. Ngale ndlela, imfucuza yefayibhu isetshenziswa kabusha ngqo ukukhiqiza i-fiber, imfucuza ye-preform isetshenziswa ngqo ukukhiqiza ama-preforms, bese imfucuza yefilimu isetshenziswa kabusha ngqo ukukhiqiza ifilimu.

Ukuvuselelwa kwebhodlela le-PET

Ukuhlanzwa kanye nokubulawa kwezisu

Impumelelo yanoma yimuphi umqondo wokuphinda usebenze kabusha ifihlekile ekusetshenzisweni kokuhlanzwa kanye nokucwaswa endaweni efanele ngesikhathi sokucubungula kanye nasezingeni elifunekayo noma elifiswayo.

Ngokuvamile, okulandelayo kuyasebenza: Okuphambili kwinqubo yezangaphandle kukhishwa, futhi lapho lokhu kwenziwa ngokucophelela, inqubo esebenza kahle isebenza.

Okuphezulu I-Plasticizer izinga lokushisa kwe-PET ebangeni lama-280 ° C (536 ° F) yisizathu sokuthi kungani cishe konke ukungcola okuvamile okufana PVC, I-PLA, i-polyolefin, imicu yezinkuni zamakhemikhali nemicu yamaphepha, i-polyvinyl acetate, ncibilika ukunamathela, ama-ejenti wokufaka imibala, ushukela, kanye amaprotheni Izinsalela ziguqulwa zibe yimikhiqizo yokucekelwa phansi enemibala, yona, engadedela ngokungeziwe imikhiqizo yokwehla kokuwohloka. Ngemuva kwalokho, inani lokukhubazeka kuketanga le-polymer landa kakhulu. Ukusatshalaliswa kosayizi wezinhlayiyana kubanzi kakhulu, izinhlayiya ezinkulu zama-60-1000 µm — abonakala ngamehlo futhi kulula ukuwahlunga — amele ububi obuncane, ngoba ingqikithi yawo incane kakhulu futhi isivinini sokonakala sincane. Umthelela wezinhlayiya ezincanyana, okuthi — ngoba ziningi — zandisa imvamisa yokukhubazeka ku-polymer, mkhulu kakhulu.

Isiqubulo esithi “Lokho iso elingakuboni inhliziyo alikwazi ukudabuka” kubhekwa njengokubaluleke kakhulu ezinhlelweni eziningi zokuphinda zisetshenziswe. Ngakho-ke, ngaphandle kokuhlunga okusebenzayo, ukususwa kwezinhlayiya ezibonakalayo zokungcola ngokuncibilikisa izinqubo zokuhlunga kudlala indima ethile kuleli cala.

Ngokuvamile, umuntu angasho ukuthi izinqubo zokwenza ama-PET flakes flakes kusuka kumabhodlela aqoqiwe ahlukahluka njengoba imifudlana ehlukene kadoti ihlukile ekubunjweni nasezingeni layo. Ngokubheka ubuchwepheshe ayikho indlela eyodwa yokwenza. Okwamanje, kunezinkampani eziningi zobunjiniyela ezinikezela ngezitshalo nezakhi zokukhiqiza amaflake, futhi kunzima ukunquma ngesakhiwo esisodwa noma esinye sezitshalo. Noma kunjalo, kunezinqubo ezihlanganyela iningi lalezi zimiso. Ngokuya ngobuningi kanye nezinga lokungahlanzeki kwezinto zokufaka, kusetshenziswa izinyathelo ezijwayelekile zenqubo elandelayo.

- Ukuvula kwe-Bale, ukuvulwa kwe-briquette

- Ukuhlunga nokukhethwa kwemibala ehlukene, ama-polymers angaphandle ikakhulukazi iPVC, izindaba zakwamanye amazwe, ukususwa kwefilimu, iphepha, ingilazi, isihlabathi, umhlabathi, amatshe, nezinsimbi

- Ukugeza kuqala ngaphandle kokusikwa

- Ukusika okuhlanganisiwe noma kuhlanganiswe ngaphambi kokugeza

- Ukususwa kwamatshe, ingilazi nensimbi

- Ukuhlungwa komoya ukususa ifilimu, iphepha kanye namalebula

- Ukugaya, yomile futhi / noma imanzi

- Ukususwa kwama-polymers aphansi kakhulu (izinkomishi) ngokwahluka kwabantu

- Ukugeza okushisayo

- Ukugeza kwe-Caustic, kanye nokuqina komzimba, ukugcina ukubukeka okungaphakathi kanye nokubola

- I-Rinsing

- Hlanza i-rinsing yamanzi

- Ukumisa

- Ukuhlungwa komoya okuphephuka umoya

- Ukuhlelwa kwe-Flake okuzenzakalelayo

- Umjikelezo wamanzi kanye nobuchwepheshe bokwelashwa kwamanzi

- Ukulawulwa kwekhwalithi ye-Flake

Ukungcola kanye nokulimala kwezinto ezibonakalayo

Inani lokungcoliseka okungenzeka kanye nokulimazeka kokuthile okuqongelela kokuqukethwe kwepolymeric kukhula unomphela — lapho kucutshungulwa futhi kusetshenziswa ama-polymers — kubheka isikhathi sokukhula senkonzo esandayo, ukukhula kokugcina kokusebenza nokuphindaphinda okuphindaphindwayo. Ngokuqondene namabhodlela we-PET asetshenziswe kabusha, iziphambeko ezishiwoyo zingahlelwa emaqenjini alandelayo:

- Amaqembu e-polyester asebenzayo e-ReH noma e-COOH- aguqulwa aguqulwa aba amaqembu wokugcina noma ongasebenzi, isb ukwakhiwa kwamaqembu we-vinyl ester end ngokusebenzisa ukuphuma komzimba noma i-decarboxylation ye-terephthalate acid, ukusabela kwamaqembu we-OH- noma we-COOH- ngokuwohloka kokusebenza okuphansi imikhiqizo efana nama-mono-carbonic acid noma ama-alcohols. Imiphumela incishisiwe ukuphinda isebenze phakathi kokuvuselelwa kabusha kwe-polycolfund noma i-SSP futhi kusakazwa ukusatshalaliswa kwesisindo semolekyuli.

- Ingxenye yeqembu lokugcina igudlulela ekuqondeni kwamaqembu wokuphela we-COOH akhiwe ngokudilizwa okushisayo nokunama-oxidative. Imiphumela iyancipha ekuphindweni kabusha, kanye nokwanda kokuwohloka kwe-asidi autocatalytic ngesikhathi sokwelashwa okushisayo lapho kunomswakama.

- Inani lama-macromolecule e-polyfunctional landa. Ukutholakala kokukhubazeka kwama-gels kanye nezikhala ze-branching ende ezinde.

- Inombolo, ukugxilisa ingqondo, kanye nezinhlobonhlobo zezinto eziphilayo ezingenzi mpilo nezezinto zakwamanye amazwe ziyanda. Ngayo yonke imbandezelo entsha eshisayo, izinto eziphilayo zakwamanye amazwe zizosabela ngokuwohloka. Lokhu kudala ukukhululwa kwezinto ezisekela ukonakala nezinto ezinemibala.

- Amaqembu e-Hydroxide ne-peroxide akha phezulu kwemikhiqizo eyenziwe nge-polyester phambi komoya (umoya-mpilo) nomswakama. Le nqubo isheshiswa ukukhanya kwe-ultraviolet. Ngesikhathi senqubo yokwelashwa engaphandle, ama-hydro peroxides angumthombo wama-oksijini we-oxygen, okuwumthombo wokuwohloka kwe-oxidative. Ukubhujiswa kwe-hydro peroxides kufanele kwenzeke ngaphambi kokulashwa kokuqala kokushisa noma ngesikhathi sopulasitiki futhi kungasekelwa izengezo ezifanelekileyo njengama-antioxidants.

Ngokubheka ukonakala nokungcola kwamakhemikhali okushiwo ngenhla, kunokuguqulwa okuqhubekayo kwezimpawu ezilandelwayo zepolymer phakathi nomjikelezo ngamunye wokuphinda usebenzise, ezitholakala ngokuhlaziywa kwamakhemikhali nawomzimba.

Ngokuqondene:

- Ukwanda kwamaqembu wokugcina we-COOH

- Ukwanda kwenombolo yemibala b

- Ukwanda kwamehlo (imikhiqizo esobala)

- Ukwanda kokuqukethwe kwe-oligomer

- Ukwehliswa kokuhlunga

- Ukwanda kokuqukethwe kwemikhiqizo yemikhiqizo efana ne-acetaldehyde, formaldehyde

- Ukwanda kokungcola okungaphandle kwangaphandle

- Yehlisa ngombala L

- Ukuncipha kwe ukubukeka okungaphakathi noma amandla okubonisa amandla

- Ukwehla kwezinga lokushisa kwe-crystallization kanye nokwanda kwejubane le-crystallization

- Ukwehla kwezakhiwo zemishini njengamandla amancane, ukusangana ngekhefu noma modulus nokunwebeka

- Ukusakazwa kokusatshalaliswa kwesisindo samangqamuzana

Ukuvuselelwa kabusha kwamabhodlela e-PET kumanje inqubo evamile yezimboni enikezwa izinkampani eziningi zobunjiniyela.

Icubungula izibonelo ze-polyester eyenziwe kabusha

Izinqubo zokuphinda zisetshenziswe nge-polyester zicishe zehluke njengezinqubo zokukhiqiza ezisuselwa kuma-pellets ayisisekelo noma ancibilike. Ngokuya ngobumsulwa bezinto ezenziwe kabusha, i-polyester ingasetshenziswa namuhla ezinqubweni eziningi zokukhiqiza ze-polyester njengokuhlangana ne-virgin polymer noma ngokuya njenge-polymer eyenziwe kabusha engu-100%. Okunye okuhlukile okufana nefilimu ye-BOPET yobukhulu obuphansi, izinhlelo zokusebenza ezikhethekile ezifana nefilimu ebonakalayo noma izintambo nge-FDY-spinning ku-> 6000 m / min, microfilaments, kanye ne-micro-fibers kukhiqizwa kusuka ku-polyester eyintombi kuphela.

Ukuvuselelwa kabusha okulula kwamabhodlela ebhodlela

Le nqubo iqukethe ukuguqula imfucumfucu yamabhodlela ibe ngamachashaza, ngokusula nangokukhipha amalahle, ngokufaka amapulasitiki nokufafaza, nangokuthambisa. Umkhiqizo ukwakhiwa kabusha okufakazayo kokubonakalayo okungaphakathi kobubanzi be-0.55-0.7 dℓ / g, kuye ngokuthi kwenziwa kanjani ngaphambi kokomiswa kwama-PET flakes.

Izici ezikhethekile yilezi: i-Acetaldehyde ne-oligomers zitholakala kuma-pellets ezingeni eliphansi; i-viscosity iyancishiswa ngandlela thile, ama-pellets ane-amorphous futhi kufanele afakelwe i-crystallized futhi omiswe ngaphambi kokucutshungulwa okwengeziwe.

Icubungula ku:

- Ifilimu le-A-PET le i-thermoforming

- Isengezo ekukhiqizeni izintombi ze-PET

- I-BoPET ifilimu yokufaka

- Ibhodlela le-PET i-resin yi-SSP

- Intambo ekhaphethi

- Ubunjiniyela beplastiki

- Amafilimu

- Okungahlosiwe

- Imivimbo yokupakisha

- Isicubu se-fiber.

Ukukhetha indlela yokuphindisela kabusha kusho ukuba nenqubo eyengeziwe yokuguqula okungukuthi, ohlangothini olulodwa, olunamandla futhi olonga imali, futhi olubangela ukubhujiswa okushisayo. Ngakolunye uhlangothi, isinyathelo se-pelletizing sinikeza izinzuzo ezilandelayo:

- Okujulile kuncibilikiswa

- Ukulawulwa kwekhwalithi ephakathi

- Ukuguqulwa ngezithasiselo

- Ukukhethwa komkhiqizo kanye nokuhlukaniswa ngekhwalithi

- Icubungula ukuguquguquka kukhuphukile

- Ukufaniswa kwekhwalithi.

Ukukhiqizwa kwama-PET-pellets noma ama-flakes amabhodlela (ibhodlela kuya kwibhodlela) kanye ne-A-PET

Le nqubo, ngokomthetho, iyafana nale echazwe ngenhla; kodwa-ke, ama-pellets akhiqizwayo ahlanganiswe ngqo (ngokuqhubekayo noma ngokunganqamuki) abese enikezwa i-solid-state polycondensation (SSP) endaweni eyomayo ewisayo noma mpo we-tube reactor. Ngalesi sinyathelo sokucubungula, i-viscosity ehambelana nalokho eyi-0.80-0.085 dℓ / g iyakhiwa kabusha futhi, ngasikhathi sinye, okuqukethwe kwe-acetaldehyde kwehliselwa ku- <1 ppm.

Iqiniso lokuthi abanye abakhiqizi bemishini nabakhi bemigqa eYurophu naseMelika benza imizamo yokuhlinzeka ngezinqubo ezizimele zokuphinda kusetshenziswe kabusha, isib. Inqubo ebizwa ngokuthi yibhodlela-ibhodlela (B-2-B), efana nenqubo I-BePET, InkanyeziI-URRC noma i-BÜHLER, ihlose ukunikeza ubufakazi bokuthi "kukhona" izinsalela ezidingekayo zokukhishwa kanye nokususwa kokungcolisa okuyisibonelo ngokusho kwe-FDA esebenzisa lokho okuthiwa yi-test test, okudingekayo ekusetshenzisweni kwe-polyester ephathekayo ku umkhakha wokudla. Ngaphandle kwalokhu kugunyazwa kwenqubo kuyadingeka ukuthi noma yimuphi umsebenzisi walezi zinqubo kufanele ahlole njalo imikhawulo ye-FDA ngezinto zokusetshenziswa ezenziwe nguye ngenqubo yakhe.

Ukuguqulwa okuqondile kwamabhodlela ebhodlela

Ukuze wonge izindleko, inani elikhulayo labakhiqizi abaphakathi be-polyester bathinta izinsika zokuphotha, imishini yokugaya, noma ama-mill mill wefilimu basebenza ngokusetshenziswa okuqondile kwe-PET-flakes, kusukela ekwelashweni kwamabhodlela asetshenzisiwe, ngenhloso yokwakha okwandayo. inani labalingisi be-polyester. Ukuze kulungiswe i-viscosity edingekayo, ngaphandle kokomiswa okusebenzayo kwama-flakes, kungenzeka kudingekile ukuthi uphinde wakhe kabusha i-viscosity ngokusebenzisa polycondroll esigabeni esincibilikayo noma i-state-state polycondbuyekezo eqinile yamabhuki. Izinqubo zakamuva zokuguqula i-PET flake zisebenzisa ama-screw extruders, ama-extruders ama-screw amaningi noma ama-rotation ejikelezayo kanye nokususa i-vacuum okuvumelanayo ukuze kususwe umswakama futhi kugwenywe ukomiswa kwangaphambili. Lezi zinqubo zivumela ukuguqulwa kwamafulethi we-PET angashintshiwe ngaphandle kokuncipha okukhulu kwe-viscosity okubangelwa yi-hydrolysis.

Mayelana nokusetshenziswa kwamafulethi webhodlela le-PET, ingxenye enkulu cishe engama-70% iguqulwa ibe yimicu nemicibisholo. Lapho usebenzisa izinto zokwakha ezihlanganisiwe ngokuqondile ezifana nezikabha zamabhodlela ezinqubweni zokuphotha, kukhona izimiso ezimbalwa zokucubungula ongazithola.

Izinqubo zokuphotha ngesivinini esikhulu zokwenza i-POY zivame ukudinga ukubonwa okungu-0.62-0.64 dℓ / g. Ukusuka kumabhodlela ebhodlela, i-viscosity ingasetwa ngezinga lokoma. Ukusetshenziswa okwengeziwe kwe-TiO2 iyadingeka ukuze kutholakale umugqa ogcwele noma owubuthuntu obuthuntu. Ukuze uvikele ama-spinnerets, ukuhlunga okusebenzayo kokuncibilika kungukuthi, kunoma yisiphi isimo siyadingeka. Okwesikhathi esikhona, inani le-POY elenziwe nge-100% kabusha iphayiphu liphansi ngoba le nqubo idinga ukuhlanzeka okuphezulu kokuncibilika kokuncibilika. Esikhathini esiningi, kuhlanganiswa izinhlanganisela zama-pellets ezihamba nezintombi.

Imicu eyisiqalo ihlakazekile ebangeni le-viscosity ebonakala ukuthi isephansi futhi okufanele ibe phakathi kuka-0.58 no-0.62 dℓ / g. Kulesi simo, futhi, i-viscosity edingekayo ingashintshwa ngokumiswa noma ngokulungiswa kwe-vacuum uma kwenzeka ukuphuma kwe-vacuum. Ukulungisa ukubonwa, noma kunjalo, ukungezwa kokulinganisa ubude be-chain i-ethylene glycol or i-diethylene glycol lungasetshenziswa.

Ukuphina okungalukwanga-emkhakheni omuhle we-titer wezicelo zezindwangu kanye nokuxubha okusindayo okungasokiwe njengezinto eziyisisekelo, isib. Izembozo zophahla noma ekwakhiweni komgwaqo — kungenziwa ngemishini eshintshanisa amabhodlela. Isibuko sokuphinda siphinde sibe phakathi kwebanga le-0.58-0.65 dℓ / g.

Enye inkambu yenzalo eyandayo lapho kusetshenziswa izinto zokuphinda kusetshenziswe kabusha imishini emincane yokufakelwa, kanye nama-monofilaments. Kuzona zozimbili lezi zinhlobo, okwenziwe ngqa kokuqala kungokuqukethwe okubuye kusetshenziswwe kabusha kokubonisa okuphezulu kokuqonda. Imichilo yokufaka ephezulu ye-tenacity kanye ne-monofilament iyenziwa lapho kwenziwa inqubo yokuxubha yokuncibilika.

Ukuphinda usebenzise ama monomers

I-polyethylene terephthalate ingathathelwa indawo ukuze ikhiqize ama monomers abakhethayo. Ngemuva kokuhlanzwa, ama-monomers angasetshenziswa ukulungisa i-polyethylene terephthalate entsha. Amabhondi we-ester ku-polyethylene terephthalate angaqedwa yi-hydrolysis, noma ngokudluliselwa. Ukuphendula kumane kuwukuphindisela kwalabo abasetshenzisiwe ekukhiqizeni.

Ingxenye ye-glycolysis

I-glycolysis engxenye (transesteration ne-ethylene glycol) iguqula i-polymer eqinile ibe ama-oligomers anemikhono emifushane angancibilikiswa ngokushisa okuphansi. Lapho sebekhululiwe kokungcoliswa, ama-oligomers angadliwa abuyele ohlelweni lokukhiqiza lwe-polymerization.

Umsebenzi uqukethe ekondleni ama-10-25% wamabhodlela webhodlela ngenkathi kulondolozwa ikhwalithi yamaphayini webhodlela akhiqizwa emgqeni. Le nhloso ixazululwa ngokudicilela phansi imfucumfucu yamabhodlela we-PET — esesivele ngesikhathi sokupulasitiki kokuqala, okungenziwa endaweni eyodwa noma isikulufa esilinganayo — ekubonaka okungaphakathi kwe-0.30 dℓ / g ngokungeza inani elincane le-ethylene glycol kanye Ngokufaka ukuthambeka okungaphansi kokuncibilikisa kuncibilikise ekugcwalisweni okusebenzayo ngqo ngemuva kopulasitiki. Ngaphezu kwalokho, amazinga okushisa alethwa umkhawulo ophansi kakhulu. Ngaphezu kwalokho, ngale ndlela yokucubungula, kungenzeka ukuthi ukubumbeka kwamakhemikhali kwe-hydro peroxides kungenzeka ngokungeza i-P-stabilizer ehambisanayo ngqo lapho iplasitiki. Ukubhujiswa kwamaqembu we-hydro peroxide,, nezinye izinqubo, sekuvele kwenziwa ngesikhathi sesinyathelo sokugcina sokwelashwa kwe-flake ngokwesibonelo ngokungeza uH3PO3. Izinto ezenziwe kabusha ezi-glycolyzed futhi ezihlungwe kahle ziqhubeka zondliwa ku-esterification noma isiphenduli se-prepolycondensation, ubuningi bokulinganisa kwezinto zokusetshenziswa kulungiswa ngokufanele.

Ingqikithi ye-glycolysis, i-methanolysis, ne-hydrolysis

Ukwelashwa kokungcola kwe-polyester ngokusebenzisa i-glycolysis ephelele ukuguqula ngokuphelele i-polyester ibe bis (2-hydroxyethyl) terephthalate (C6H4(CO2CH2CH2OH)2). Le khompiyutha ihlanjululwa yi-vacuum distillation, futhi ingesinye sezimpawu ezisetshenziselwa ukwenziwa kokwenza i-polyester. Ukusabela okuhilelekile kungokulandelayo:

- [(CO) C6H4(CO2CH2CH2O)]n + n Hoch2CH2OH → n C6H4(CO2CH2CH2OH)2

Le ndlela yokuphinda isebenze yenziwe yezinga lezimboni eJapan njengomkhiqizo wokuhlola.

Ifana ne-glycolysis ephelele, i-methanolysis iguqula i-polyester ibe i-dimethyl terephthalate, engahlungwa bese kuthathwa insimbi:

- [(CO) C6H4(CO2CH2CH2O)]n + 2n CH3OH → n C6H4(CO2CH3)2

I-Methanolysis ayivamisile ukwenziwa embonini namuhla ngoba ukukhiqizwa kwe-polyester ngokusekelwe kwi-dimethyl terephthalate kuye kwashuba kakhulu, futhi abakhiqizi abaningi be-dimethyl terephthalate banyamalala.

Futhi njengoba ngenhla, i-polyethylene terephthalate ingafakwa hydrolyzed to terephthalic acid kanye i-ethylene glycol ngaphansi kokushisa okuphezulu nokucindezela. Umphumela we-terephthalic acid ongumphumela ungahlanzwa yi ukuphinda usebenzise kabusha ukukhiqiza izinto ezilungele ukuphindiswa kabusha polymerization:

- [(CO) C6H4(CO2CH2CH2O)]n 2 +n H2O → n C6H4(CO2H)2 + n Hoch2CH2OH

Le ndlela kubonakala ngathi ayikaze ithengiswe.