I-EBM

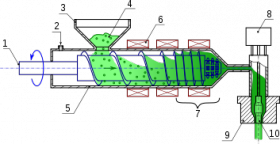

In I-extrusion Blow Molding (I-EBM), ipulasitiki iyancibilika futhi ifakwe emgodini oyimbumba (parison). Le parison iyabanjwa ngokuyivala ifakwe kwisikhunta sensimbi esetshenzisiwe. Umoya ube usushaywa uphethiloli, uwukhuphule ekuthini ubumbeke ibhodlela, isitsha, noma ingxenye. Ngemuva kokuthi upulasitiki usupholile ngokwanele, isikhunta siyavulwa bese kuthi ingxenye leyo ikhutshwe. Okuqhubekayo kanye nokuhlosiwe kungukuhluka okubili kwe-extrusion Blow Molding. Ngokuqhubeka kwe-extrusion Blow Ukubumba i-parison kukhishwa ngokuqhubekayo futhi izingxenye ezithile zinqunywa ngommese ofanele. E-Intermittent blowing forming kunezinqubo ezimbili: ukunqamula okuqondile kufana nokufakwa komjovo lapho isikulufa siphenduka khona, bese kuyema bese kusunduza kuncibilike. Ngendlela yokuqongelela, isithangi sibutha ipulasitiki elicibilikile futhi lapho isikhunta sangaphambilini sesipholile futhi ipulasitiki eyanele iqoqekile, induku idonsa ipulasitiki encibilikisiwe futhi yakha parison. Kulokhu isikulufa singaphenduka ngokuqhubekayo noma njalo. ngokusikhipha okuqhubekayo isisindo se-parison sidonsela umhlanganiso futhi sikwenze kube nzima ukushuba kogange. Ikhanda le-accumulator noma izindlela zokuphinda zisebenzise i-hydraulic system ukusunduza i-parison ukuphuma ngokushesha ukunciphisa umphumela wesisindo nokuvumela ukulawula okuqondile phezu kogqinsi lwedonga ngokulungisa igebe lokufa ngohlelo lwe-parison programming.

Izinqubo ze-EBM kungahle kube okuqhubekayo (ukukhipha i-parison engapheli) noma ukwedlula. Izinhlobo zemishini ye-EBM zingahlukaniswa ngezigaba ezilandelayo:

Imishini yokufukuza eqhubekayo

- amasistimu wokujikeleza wokushayela amasondo

- imishini eshelelayo

Imishini esezingeni eliphakathi nendawo

- imishini yokubuyisela isikulufa

- imishini yokuqongelela ikhanda

Izibonelo zezingxenye ezenziwe inqubo ye-EBM zifaka imikhiqizo eminingi engenalutho ye-polyethylene, amabhodlela obisi, i-shampoo amabhodlela, ukugaya izimoto, ukuthambisa amathini nezingxenye zezimboni eziyize njengezigubhu.

Izinzuzo zokubumba ngokushaywa zifaka: ithuluzi eliphansi nezindleko zokufa; amanani okukhiqiza asheshayo; ikhono lokubumba ingxenye eyinkimbinkimbi; Izibambo zingafakwa ekwakhiweni.

Izinkinga zokubumba ngokushaywa zifaka: ukukhawulelwa ezingxenyeni ezingenamkhawulo, amandla aphansi, ukuze kwandiswe izithikamezo zokuphamba kwezinto eziningi ze-multilayer zezinto ezahlukahlukene ezisetshenziswayo ngakho-ke azikwazi ukuphindwaphindwa. Ukuze wenze izimbambo ezibanzi zentamo ebanzi kuyadingeka

Ukusika kwesipin

Iziqukathi ezinjengezimbiza zivame ukuba nokuningi ngokweqile ngenxa yenqubo yokubumba. Lokhu kuncishiswa ngokunwebeza ummese ezungeze esitsheni okusika lokho. Le pulasitiki eyeqisayo iyasetshenziswa kabusha ukuze kwakheke ukubumba okusha. Ama-Spin Trimmers asetshenziswa ezintweni eziningi zokwakha, njenge-PVC, i-HDPE ne-PE + LDPE. Izinhlobo ezahlukene zezinto zokwakha zinezimpawu zazo zomzimba ezithinta ukunqunqa. Isibonelo, ama-moldings akhiqizwa ngezinto zokwakha amorphous kunzima kakhulu ukuwanciphisa kunezinto ze-crystalline. Ama-Titanium coated blade asetshenziswa njalo kunensimbi ejwayelekile ukwandisa impilo ngesizathu sezikhathi ezingama-30.