Injection

Ukufakwa komjovo (umjovo wokubumba e-USA) inqubo yokukhiqiza yokukhiqiza izingxenye ngokujova impahla kukhunta. Ukufakwa kokulimala kungenziwa ngezinto eziningi, kufaka phakathi izinsimbi, (lapho inqubo ibizwa ngokuthi i-diecasting), izingilazi, ama-elastomers, ukuhlangana, kanye nama-polymers evamile kakhulu we-thermoplastic kanye ne-thermosetting. Indwangu yengxenye ifakwa emgqonyeni ofudumele, oxutshwe, bese ophoqelelwa kumgodi wobumba, lapho upholisa futhi uqinise ukumiswa kwelesi. Ngemuva kokuthi umkhiqizo uklanyelwe, ngokuvamile ngumklami wezimboni noma i Unjiniyela, isikhunta senziwa ngumbumbi (noma umenzi wamathuluzi) ngensimbi, imvamisa kungaba yinsimbi noma i-aluminium, futhi kwenziwe ngomshini ukuze kwenziwe izici zengxenye oyifunayo. Umjovo wokubumba usetshenziselwa kabanzi ukukhiqiza izingxenye ezahlukahlukene, kusuka ezingxenyeni ezincane kakhulu kuya kuwo wonke amaphaneli womzimba wezimoto. Intuthuko kubuchwepheshe bokuphrinta be-3D, kusetshenziswa ama-photopolymers angancibiliki ngesikhathi sokubunjwa komjovo wezinga eliphansi lokushisa kwe-thermoplastics, kungasetshenziselwa ezinye izikhunta ezilula zomjovo.

Izingxenye ezizofakwa umjovo wokujova kumele zenzelwe ngokucophelela ukwenza inqubo yokubumba; izinto ezisetshenziselwa ingxenye, ukwakheka okufisayo kanye nezici zengxenye, izinto zokubumba, kanye nezinto zomshini wokubumba kumele konke kucatshangwe. Ukuguquguquka kwezinto zokubumba umjovo kusatshalaliswa yilobu bubanzi bokucatshangwa kokuklama kanye namathuba.

Izicelo

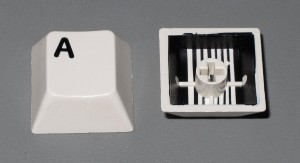

Ukubumba komjovo kusetshenziselwa ukudala izinto eziningi ezifana nama-spools we-wire, emaphaketheni, izicucu zamabhodlela, izingxenye zezimoto nezingxenye, ama-Gameboys, okokuphonsa emaphaketheni, okokusebenza okuthile komculo (nezingxenye zawo), izihlalo zentambo eyodwa namatafula amancane, iziqukathi zokugcina, izingxenye zemishini (kufaka phakathi amagiya), neminye imikhiqizo eminingi yepulasitiki etholakala namuhla. Ukubumba injekishini kuyindlela ejwayelekile kakhulu yesimanje yokwenza izingxenye zepulasitiki; ilungele ukukhiqiza amanani aphezulu ento efanayo.

Izici zokucubungula

Ukubumba injekishini isebenzisa inqama noma isikulufu sohlobo lwe-plunger ukuphoqa unyibilikisiwe plastic impahla emgodini wesikhunta; lokhu kuqina kube isimo esihambisane nentaba yesikhunta. Isetshenziswa kakhulu ukucubungula ama-polymers e-thermoplastic kanye ne-thermosetting, nevolumu esetshenzisiwe yangaphambili ibiphakeme kakhulu. Ama-Thermoplastics adlange kakhulu ngenxa yezici ezenza ukuthi zikulungele kakhulu ukubunjwa komjovo, njengokukhululeka ezingaphinde zisebenze kabusha, ukwenza kwazo izinto ezihlukahlukene kuzivumela ukuthi zisetshenziswe ezinhlotsheni ezahlukahlukene, kanye nokukwazi kwabo ukuthambisa nokugeleza lapho kushisa. I-Thermoplastics nayo inesici sokuphepha ngaphezu kwama-thermosets; uma i-polymer ye-thermosetting ingakhishwa emgqonyeni womjovo ngesikhathi esifanele, ukuxhumeka kwamakhemikhali kungahle kwenzeke kubangele ukuthi isikulufa nokuhlola ama-valve kubambe futhi kungalimaza umshini wokubumba umjovo.

Umjovo udini siqukethe umfutho ophakeme umjovo we impahla eluhlaza ibe isikhunta okuyinto bobunjwa polymer ibe ijamo oyifunayo. Isikhunta singaba nesikhala esisodwa noma izimbotshana eziningi. Ezingxenyeni eziningi zomgogodla, umgodi ngamunye ungafana futhi wakhe izingxenye ezifanayo noma ungahluka futhi wakhe ama-geometri amaningi ahlukahlukene phakathi komjikelezo owodwa. Isikhunta ngokuvamile senziwa ngezinsimbi zamathuluzi, kepha insimbi engenasici ne-aluminium isikhunta kufanelekile kuzinhlelo ezithile. Izikhunta ze-Aluminium ngokuvamile azikufanelekeli ukukhiqizwa kwevolumu ephezulu noma izingxenye ezinokubekezelelana okuncane, njengoba zinezinto eziphansi zomshini futhi zithambekele kakhulu ekugqokeni, ekonakaleni, nasekuguqukeni ngesikhathi semijikelezo yomjovo kanye nokucindezela; kodwa-ke, isikhunta se-aluminium songa izindleko ekusetshenzisweni kwevolumu ephansi, njengoba izindleko zokuklanywa kwesikhunta nesikhathi kuncishisiwe kakhulu. Izikhunta eziningi zensimbi zenzelwe ukucubungula izingxenye ezingaphezu kwesigidi ngesikhathi sokuphila kwazo futhi kungabiza amakhulu ezinkulungwane zamaRandi ukwenza lokho.

Nini ama-thermoplastics zibunjiwe, okokusebenza okuluhlaza okwenziwe oketshezi kufakwa nge-hopper emgqonyeni oshisayo ngesikulufu esivuselelayo. Ekungeneni komgqomo izinga lokushisa liyakhuphuka futhi amandla eVan der Waals amelana nokugeleza okulinganayo kwamaketanga ngamanye ayantengantenga ngenxa yesikhala esandayo phakathi kwama-molecule ezindaweni eziphezulu zamandla okushisa. Le nqubo inciphisa i-viscosity yayo, eyenza i-polymer igeleze ngamandla okushayela weyunithi yomjovo. Isikulufa sihambisa okokusetshenziswa okuluhlaza phambili, kuxuba futhi kuhambise ukusabalalisa okushisayo nokunamandla kwe-polymer, futhi kunciphise isikhathi sokushisa esidingekayo ngokugunda okokusebenza futhi kungeze inani elikhulu lokushisa okungqubuzanayo ku-polymer. Okuphakelayo kudlulela phambili nge-valve yesheke bese kuqoqwa ngaphambili kwesikulufo kube yivolumu eyaziwa njenge shot. Ukudutshulwa ivolumu yento esetshenziselwa ukugcwalisa isikhunta sesikhunta, ukunxephezela ukuncipha, nokunikeza isiguqo (cishe u-10% wevolumu yethotho eliphelele, elihlala emgqonyeni futhi livimbele isikulufa ekuphumeni) ukudlulisa ingcindezi kusukela isikulufu imbobo isikhunta. Lapho izinto ezanele seziqoqiwe, okokusebenza kuphoqelelwa ekucindezelweni okuphezulu kanye ne-velocity engxenyeni yokwakha ingxenye. Ukuvimbela ama-spikes ekucindezelekeni, inqubo ijwayele ukusebenzisa indawo yokudlulisa ehambelana nesikhala esigcwele esingu-95-98% lapho isikulufu sisuka khona ku-velocity engaguquki iye ekulawuleni ingcindezi njalo. Imvamisa izikhathi zomjovo zingaphansi kwesekhondi elilodwa. Lapho isikulufa sifinyelela lapho kudluliswa khona ingcindezi yokupakisha iyasetshenziswa, eqeda ukugcwaliswa kwesikhunta futhi inxephezele ukuncipha okushisayo, okuphezulu kakhulu kuma-thermoplastics ahlobene nezinye izinto eziningi. Ingcindezi yokupakisha isetshenziswa kuze kuqiniswe isango (ukungena komgodi). Ngenxa yobukhulu bayo obuncane, isango imvamisa liyindawo yokuqala yokuqinisa ngogqinsi lwalo lonke. Lapho isango seliqinile, akusekho okokusebenza okungangena emgodini; ngokufanele, isikulufa siyabuyisela futhi sithole okokusebenza kumjikelezo olandelayo ngenkathi okokusebenza ngaphakathi kwesikhunta kuphola ukuze kukhishwe futhi kuzinze ngokulinganayo. Lesi sikhathi sokupholisa sincishiswe ngokuphawulekayo ukusetshenziswa kwemigqa yokupholisa ehambisa amanzi noma uwoyela kusuka kusilawuli sokushisa sangaphandle. Lapho nje izinga lokushisa elidingekayo selitholakele, isikhunta siyavuleka bese kutholwa izikhonkwane eziningi, imikhono, okokuhlwaya, njll. Ngemuva kwalokho, isikhunta siyavala bese inqubo iphindaphindwa.

Kuma-thermosets, ngokuvamile izingxenye ezimbili zamakhemikhali ezihlukene zifakwa emgqonyeni. Lezi zingxenye ziqala ngokushesha ukusabela kwamakhemikhali ezingenakuphikiswa ezigcina zidlulisele okuqukethwe kwinethiwekhi eyodwa exhunyiwe yama-molecule. Lapho ukusabela kwamakhemikhali kwenzeka, lezi zingxenye ezimbili zamanzi ziguqula unomphela zibe yi-viscoelastic solid. Ukuqiniswa emgqonyeni womjovo naku-screw kungaba yinkinga futhi kube nemiphumela yezimali; ngakho-ke, ukunciphisa ukwelashwa kwe-thermoset ngaphakathi komgqomo kubalulekile. Lokhu kusho ukuthi isikhathi sokuhlala kanye nokushisa kwama-precursors amakhemikhali kuncishisiwe kuyunithi lomjovo. Isikhathi sokuhlala singancishiswa ngokunciphisa umthamo wevolumu yomgqomo nangokwandisa izikhathi zomjikelezo. Lezi zinto ziholele ekusetshenzisweni kwento ehlukanisiwe ngokushisa, ebandayo ejova amakhemikhali aphendulayo kwisikhunta esishisayo esihlukaniswe ngokushisa, okwandisa izinga lokuphendula kwamakhemikhali futhi kuholele esikhathini esifushane esidingekayo ukufeza ingxenye eqinile ye-thermoset. Ngemuva kokuthi ingxenye iqinile, amavalvu asondele ekuhlukaniseni uhlelo lokujova kanye nezandulela zamakhemikhali, bese isikhunta sivuleka ukukhipha izingxenye ezibunjiwe. Ngemuva kwalokho, isikhunta siyavala bese inqubo iphinda.

Izakhi ezenziwe ngaphambi kokubumba noma ezenziwe ngomshini zingafakwa emgodini ngenkathi isikhunta sivulekile, okuvumela lokho okufakwa kulayini womjikelezo olandelayo ukwakha futhi kuqinise ukuzungeza kwabo. Le nqubo yaziwa ngokuthi Faka isikhunta futhi ivumela izingxenye ezizodwa ukuthi ziqukethe izinto eziningi. Le nqubo ivame ukusetshenziselwa ukudala izingxenye zepulasitiki ezinezikulufu zensimbi ezivelelayo, ezivumela ukuba ziboshwe futhi zingagxiliswa kaninginingi. Le ndlela ingasetshenziselwa ukulebula kwe-In-mold kanye namabhodlela efilimu nawo angaxhunywa ezitsheni zepulasitiki ezibunjiwe.

Ulayini wokuhlukanisa, i-sprue, amamaki esango, namamaki we-ejector pin ngokuvamile akhona engxenyeni yokugcina. Azikho kulezi zici ezivame ukufiseleka, kepha azigwemeki ngenxa yenqubo. Amamaki esango ayenzeka esangweni elijoyina iziteshi ezincibilikisa ukulethwa (i-sprue nomgijimi) engxenyeni eyakha umgodi. Umugqa wokuhlukanisa namamaki we-ejector pin kubangelwa ukungalungiswa kahle kweminithi, ukugqoka, ukuvuleka kwegesi, ukuvunyelwa kwezingxenye eziseduze nokunyakaza okuhlobene, kanye / noma umehluko wobukhulu bezindawo zokumatanisa ezixhumana ne-polymer ejojowe. Umehluko wobukhulu ungabangelwa ukungafani, ukucindezelwa okubangelwa ingcindezi ngesikhathi somjovo, ukubekezelelana kwemishini, nokunwetshwa okungafani kokushisa nokuncipha kwezingxenye zesikhunta, ezihlangabezana nokuhamba ngebhayisikili okusheshayo ngesikhathi somjovo, ukupakisha, ukupholisa, kanye nezigaba zokukhishwa kwenqubo . Izingxenye zesikhunta zivame ukwakhiwa ngezinto zokwenziwa kwama-coefficients ahlukahlukene wokunwetshwa okushisayo. Lezi zinto azikwazi ukubalwa ngasikhathi sinye ngaphandle kokunyuka kwezinkanyezi ezindlekweni zokwakhiwa, ukwenziwa, ukucubungulwa, nokuqapha ikhwalithi. Isikhunta esinekhono nomklami oyingxenye sizobeka lokhu kulimaza ubuhle ezindaweni ezifihlekile uma kungenzeka.

Umlando

Umsunguli waseMelika uJohn Wesley Hyatt kanye nomfowabo u-Isaiah, uHyatt unelungelo lobunikazi lomshini wokuqala wokubumba umjovo ngo-1872. Lo mshini wawungelula uma uqhathaniswa nemishini esetshenziswayo namuhla: wawusebenza njengenaliti enkulu ye-hypodermic, usebenzisa i-plunger ukujova ipulasitiki ngentuthu isilinda sibe isikhunta. Imboni yathuthuka kancane ngokuhamba kweminyaka, ikhiqiza imikhiqizo efana nokuhlala kwekhola, izinkinobho nezinkinobho zezinwele.

Ochwepheshe bamakhemikhali baseJalimane u-Arthur Eichengrün noTheodore Becker basungula izinhlobo zokuqala ze-cellulose acetate ngo-1903, ezazingashisi kangako kune-cellulose nitrate. Yagcina yenziwe yatholakala ngefomu le-powder lapho kwakulungiswa khona umjovo. U-Arthur Eichengrün wenza umshini wokuqala wokulolonga ngomjovo ngo-1919. Ngo-1939, u-Arthur Eichengrün wanika igunya lokulimaza umjovo we-cellulose acetate epulasitiki.

Umkhakha wakhula ngokushesha ngawo-1940 ngoba iMpi Yezwe II yakha isidingo esikhulu semikhiqizo engabizi, ekhiqizwa ngobuningi. Ngo-1946, umsunguli waseMelika uJames Watson Hendry wakha umshini wokujova wokuqala wesikulufa, owawuvumela ukulawula okuqondile kakhulu kwejubane lomjovo nekhwalithi yezindikimba ezikhiqizwayo. Lo mshini ubuye wavumela ukuthi izinto zixutshwe ngaphambi kokujova, ukuze ipulasitiki enemibala noma eyenziwe kabusha iphindwe ifakwe kwinto esezintombini bese ihlanganiswa ngokuphelele ngaphambi kokujova. Namuhla imishini yokujova isikulufa ibanga iningi labo bonke imishini yokujova. Ngeminyaka yo-1970, uHendry uqhubekile nokwakha inqubo yokuqala yokusungulwa kwejozi elasizwa ngegesi, elalivumela ukukhiqizwa kwezindatshana eziyinkimbinkimbi, eziyize ezaphola ngokushesha. Lokhu kuthuthukise kakhulu ukuguquguquka kwesakhiwo kanye namandla nokuqedwa kwezingxenye ezenziwe ngenkathi kunciphisa isikhathi sokukhiqiza, izindleko, isisindo nemfucuza.

Umkhakha wokubumba ngenaliti wepulasitiki uvele ngokuhamba kwesikhathi kusuka ekukhiqizeni ama-combs nezinkinobho ukukhiqiza uhlu oluningi lwemikhiqizo yezimboni eziningi kufaka phakathi izimoto, ezokwelapha, i-aerospace, imikhiqizo yabathengi, amathoyizi, amapayipi, ukufakwa, nokwakhiwa.

Izibonelo zama-polymers afanelekela kakhulu inqubo

Ama-polymers amaningi, kwesinye isikhathi abizwa ngokuthi ama-resins, angasetshenziswa, kufaka phakathi wonke ama-thermoplastics, amanye ama-thermosets, namanye ama-elastomers. Kusukela ngo-1995, inani eliphelele lezinto zokwakha umjovo wokubumba linyukile ngesilinganiso sama-750 ngonyaka; kwakukhona cishe izinto eziyizi-18,000 ezitholakalayo ngenkathi kuqala lo mkhuba. Izinto ezitholakalayo zifaka phakathi ama-alloys noma ukuxutshwa kwezinto zokwenziwa ngaphambilini, ngakho abaklami bomkhiqizo bangazikhetha lezo zinto ezisethiwe kakhulu kunesakhiwo esikhulu. Izindlela ezinkulu zokukhethwa kwento zingamandla nomsebenzi owenziwayo engxenyeni yokugcina, kanye nezindleko, kodwa futhi nezinto ngazinye zinemikhakha ehlukile yokubumba okufanele ibhekwe. Ama-polymers ajwayelekile afana ne-epoxy ne-phenolic ayizibonelo zamaplastiki we-thermosetting ngenkathi i-nylon, i-polyethylene, ne-polystyrene kuyi-thermoplastic. Kuze kube muva nje ngokuqhathaniswa, iziphethu zepulasitiki bezingenakwenzeka, kepha ukuthuthuka kwezakhiwo ze-polymer kuzenza manje zisebenziseke impela. Izicelo zifaka amabhakhi wokuqinisa nokunqamula ukunqanyulwa kwewebhu kwempahla yangaphandle.

Isisetshenziswa

Imishini yokubumba umjovo iqukethe i-hopper ebonakalayo, inqama yomjovo noma uhlobo lwe-screw plunger, kanye neyunithi yokushisa. Eyaziwa nangokuthi imishini yokunyathelisa, babamba isikhunta okwakhiwe ngaso izingxenye. Imishini yokulinganisa ikalwa nge-tonnage, eveza inani lamandla okuqinisa umshini ongasebenza. La mandla agcina isikhunta sivaliwe ngesikhathi senqubo yokujova. I-Tonnage ingahluka kusuka kumathani angaphansi kwama-5 kuye ngaphezulu kwamathani we-9,000, ngamanani aphezulu asetshenziswe emisebenzini embalwa yokukhiqiza. Inani eliphelele le-clamp force elidingekayo linqunywa indawo ekhonjisiwe yengxenye ebunjiwe. Le ndawo ebekiwe iphindaphindwa ngamandla e-clamp kusuka ku-1.8 kuye ku-7.2 amathani kusentimitha ngayinye yesikwele yezindawo ezibekiwe. Njengomthetho wesithupha, amathani ama-4 noma ama-5 / ku2 ingasetshenziselwa imikhiqizo eminingi. Uma okwenziwe ngepulasitiki kuqinile, kuzodinga ingcindezi eyengeziwe yomjovo ukugcwalisa isikhunta, futhi ngaleyo ndlela kube ngothayela omkhulu wokubamba isikhunta sivaliwe. Amandla adingekayo anganqunywa futhi ngento esetshenzisiwe nosayizi wengxenye; izingxenye ezinkudlwana zidinga amandla amakhulu wokuqinisa.

Isibungu

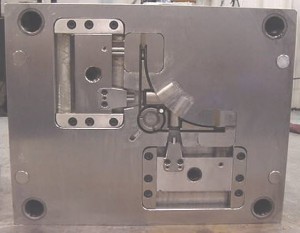

Isibungu or die yigama elijwayelekile elisetshenziselwa ukuchaza ithuluzi elisetshenziselwa ukukhiqiza izingxenye zepulasitiki ekubunjweni.

Njengoba isikhunta besibiza kakhulu ukukhiqiza, bekuvame ukusetshenziselwa ukukhiqiza ngobuningi lapho bekhiqizwa khona izinkulungwane zezingxenye. Isikhunta esijwayelekile sakhiwa ngensimbi eqinile, insimbi eyenziwe yaqina, i-aluminium, kanye / noma i-beryllium-copper alloy. Ukukhethwa kwento yokwakha isikhunta kusuka ngokuyinhloko kungokwezomnotho; Ngokuvamile, isikhunta sensimbi sibiza kakhulu ukwakha, kepha isikhathi sabo sokuphila eside sizokhipha izindleko zokuqala eziphakeme ngenani eliphakeme lezingxenye ezenziwe ngaphambi kokuguga. Izikhunta zensimbi ezenziwe pre-lukhuni zingamelana nokugqoka futhi zisetshenziselwa izidingo zevolumu ephansi noma izingxenye ezinkulu; ukuqina kwensimbi yabo ejwayelekile kungama-38-45 esikalini seRockwell-C. Izikhunta zensimbi ezilukhuni ziphathwa ukushisa ngemuva kokuchofoza; lokhu kuphakeme kakhulu ngokuya kokuqina kokuqina kanye nempilo. Ubulukhuni obujwayelekile buphakathi kwama-50 nama-60 Rockwell-C (HRC). Izikhunta ze-Aluminium zingabiza kakhulu, futhi lapho zenzelwe futhi zenziwe ngomshini wesimanje wekhompiyutha kungaba ukonga ukubumba amashumi noma izingxenye ezingamakhulu ezinkulungwane. Ithusi leBeryllium lisetshenziswa ezindaweni zesikhunta ezidinga ukususwa kokushisa okusheshayo noma izindawo ezibona ukushisa okukhulu kakhulu kukhiqizwa. Izikhunta zingenziwa noma ngemishini ye-CNC noma ngokusebenzisa izinqubo zokuphehla ugesi.

Umklamo wokwakha

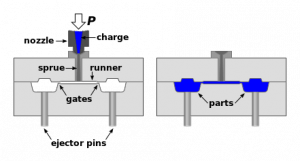

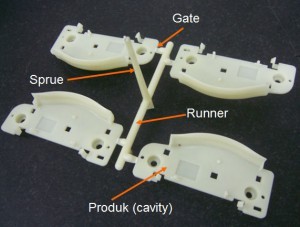

Ukubumba kuqukethe izinto ezimbili eziyinhloko, isikhunta sokujova (ipuleti) ne-ejector isikhunta (ipuleti le-B). Lezi zingxenye zibizwa nangokuthi umbumbi futhi umqambi. I-plastiki resin ingena isikhunta nge sprue or Isango isikhunta somjovo; I-sprue bushing iwukuqinisa uphawu ngokumelene nozzle wesigaxa somjovo womshini wokubumba nokuvumela ipulasitiki ebunjiwe ukuba igeleze isuka emgqonyeni ingene isikhunta, eyaziwa nangokuthi i- isikhala. I-sprue bushing iqondisa ipulasitiki ebunjiwe ezithombeni zomgodi ngemigudu eyenziwe ngomshini ebusweni bamapuleti ka-A no-B. Lezi ziteshi zivumela ipulasitiki ukuthi iqhubeke nazo, ngakho-ke zibizwa ngokuthiabagijimi. Upulasitiki oncibilikisiwe ugeleza umgijimi bese ungena esangweni elilodwa noma amaningi akhethekile futhi angene kwi-geometry yomgodi ukwakha ingxenye oyifunayo.

Inani le-resin elidingekayo ukugcwalisa i-sprue, umgijimi nezimbobo zesikhunta liqukethe "isibhamu". Umoya obhajwe kusikhunta ungaphunyuka ngemigudu yomoya egudle ulayini wokuhlukanisa isikhunta, noma izikhonkwane zama-ejector namaslayidi mancane kunezimbobo eziwagcinayo. Uma umoya obanjiwe ungavunyelwe ukuphuma, ucindezelwa ingcindezi yento engenayo futhi ucindezelwe emakhoneni omgodi, lapho uvimbela ukugcwaliswa futhi nawo ungadala ezinye iziphambeko. Umoya ungaze ucindezeleke uze ushise bese ushisa izinto zepulasitiki ezizungezile.

Ukuvumela ukususwa kwengxenye ebunjiwe kwisikhunta, izici zesikhunta akumele zigoqane enye kwesinye isiqonde lapho okuvulwa khona isikhunta, ngaphandle kokuthi izingxenye zokubumba zenzelwe ukusuka phakathi kokuphamba lapho ukubumba kuvula (kusetshenziswa izingxenye ezibizwa ngokuthi amaLifters) ).

Izinhlangothi zengxenye ezibonakala zifana nesiqondisi sokudonswa (i-axis yesikhundla esikhethiwe (umgodi) noma ukufaka kufana nokuhamba kaphezulu nokwenyuka kwesikhunta njengoba kuvula futhi kuvala) zivame ukugoqeka kancane, okubizwa ngokuthi okusalungiswa, ukunciphisa ukukhululwa kwengxenye kwisikhunta. Okusalungiswa okunganele kungadala ukusonteka noma ukulimala. Okusalungiswa okudingekayo ukuze kukhishwe isikhunta kuncike kakhulu ekujuleni komgodi: ngokujula komgodi, okusalungiswa okudingekayo ngaphezulu. Ukuncipha kufanele kubhekwe nakho lapho kunqunywa okusalungiswa okudingekayo. Uma isikhumba sincane kakhulu, ingxenye ebunjiwe izothambekela ekunciphiseni ama-cores akha ngenkathi ipholisa futhi ibambelela kulawo ma-cores, noma ingxenye ingahle igobe, isonteke, iblister noma iqhekeze lapho umgodi ukhishwa.

Isikhunta sivame ukwenziwa ukuze ingxenye ebunjiwe ihlale ngokuthembekile ohlangothini lwe-ejector (B) lwesikhunta lapho ivula, bese idonsela umgijimi no-sprue ohlangothini lwe (A) kanye nezingxenye. Ingxenye bese iwa ngokukhululeka lapho ikhishwa ohlangothini (B). Amasango emhubhe, awaziwa nangokuthi yimikhumbi-ngwenya noma isango lesikhunta, atholakala ngaphansi komugqa wokuvaleka noma isikhunta. Kuvulwa ngomshini ebusweni besikhunta kulayini wokuvalelisa. Ingxenye ebunjiwe isikiwe (yisikhunta) kusuka ohlelweni lomgijimi ku-ejection kusuka kusikhunta. Izikhonkwane ze-Ejector, ezaziwa nangokuthi izikhonkwane zokungqongqoza, ziyizikhonkwane eziyindilinga ezibekwe kuhafu yesikhunta (imvamisa isigamu se-ejector), esidudula umkhiqizo obunjiwe ophelile, noma uhlelo lomgijimi ngaphandle kwesikhunta. I-ejection yendatshana kusetshenziswa izikhonkwane, imikhono, imichilo, njll. Kungadala ukuvela okungathandeki noma ukuhlanekezela, ngakho-ke ukunakekelwa kufanele kuthathwe lapho kuklanywa isikhunta.

Indlela ejwayelekile yokupholisa idlula i-okupholisayo (imvamisa amanzi) ngokusebenzisa uchungechunge lwezimbobo eziqhutshwa amapuleti obumba bese lixhunywa ngama-hoses ukwakha indlela eqhubekayo. I-coolant ibamba ukushisa kusuka isikhunta (esesidonse ukushisa okuvela kupulasitiki oshisayo) futhi igcina isikhunta emazingeni afanele okuqinisa ipulasitiki ngesilinganiso esisebenza kahle.

Ukwenza lula ukulungiswa nokungena, izimbobo kanye nezinhlamvu zihlukaniswe zaba izicucu, zabizwa ufaka, kanye nemihlangano engezansi, ebizwa nangokuthi ufaka, izivimbela, noma ukuxosha amabhlogo. Ngokufaka ukufaka okuguqukayo okuguqukayo, isikhunta esisodwa singase senze ukuhlukahluka okuningana kwengxenye efanayo.

Izingxenye eziyinkimbinkimbi zenziwa kusetshenziswa izikhunta eziyinkimbinkimbi ngokwengeziwe. Lezi zingaba nezingxenye ezibizwa ngokuthi ama-slides, ezihamba ziye ngaphakathi kwe-cavity perpendicular ziye kwicala lokudonsa, zenze izingxenye zengezelele zengemuva. Lapho isikhunta sivulwa, amaslayidi adonswa engxenyeni yepulasitiki ngokusebenzisa “izikhonkwane” ze-stationary engxenyeni yesikhunta emile. Lezi zikhonkwane zingena ngesikhala emaslayidi futhi zibangele ukuthi ama-slides ahlehlele emuva lapho ingxenye yesikhunta evuthayo ivuleka. Ingxenye yabe isikhipha bese isikhunta sivaleka. Ukuvalwa kwesikhunta kwenza ama-slides aqhubekele phambili namaphini we-angle.

Amanye isikhunta sivumela izingxenye ezingabumba ngaphambili ukuthi ziphinde zenziwe kabusha ukuze kuvunyelwe ungqimba lwapulasitiki omusha uzungeze ingxenye yokuqala. Lokhu kuvame ukubizwa ngokuthi ukushisa ngokweqile. Lolu hlelo lungavumela ukukhiqizwa kwamathayi ecezu elilodwa namasondo.

Izikhunta ezidubuleke kabili noma ezinama-multi-shot zenzelwe "ukudlula" ngaphakathi komjikelezo owodwa wokubumba futhi kufanele zicutshungulwe kumishini ekhethekile yokubumba umjovo enezinyunithi ezimbili noma ngaphezulu zomjovo. Le nqubo empeleni iyinqubo yokubumba umjovo eyenziwe kabili ngakho-ke inephutha elincane kakhulu lephutha. Esinyathelweni sokuqala, impahla yombala oyisisekelo ibunjwe yaba ukwakheka okuyisisekelo, okuqukethe izikhala zokudubula kwesibili. Ngemuva kwalokho into yesibili, umbala ohlukile, ibunjwe ngomjovo kulezo zikhala. Ama-Pushbuttons nezinkinobho, ngokwesibonelo, ezenziwe yile nqubo zinamaki angakwazi ukuguga, futhi aqhubeke afundeka ngokusetshenziswa okunzima.

Isikhunta singaveza amakhophi amaningana wezingxenye ezifanayo "kudutshulwa" okukodwa. Inani “lokuvelayo” ekubunjweni kwaleyo ngxenye ngokuvamile libizwa ngokungalungile njenge- cavitation. Ithuluzi elinombono owodwa livame ukubizwa ngokuthi isikhunta sombono owodwa (umgodi). Ubumba olunezimbobo ezi-2 noma ezingaphezulu zezingxenye ezifanayo cishe luzobizwa ngokuthi ukubumba okuningana (i-cavity). Amanye isikhunta esiphezulu sevolumu yokukhiqiza (njengaleyo yamabhodlela amabhodlela) angaba nemikhawulo engaphezu kuka-128.

Kwezinye izimo ukusetshenziswa kwe-cavity eningi kuzokwakha uchungechunge lwezingxenye ezahlukahlukene kuthuluzi elifanayo. Abanye abenzi bamathuluzi babiza lezi zikhunta zomndeni njengoba zonke izingxenye zihlobene. Izibonelo zifaka phakathi imodeli kits epulasitiki.

Isitoreji esibunjiwe

Abakhiqizi baya ngobukhulu obukhulu ukuvikela isikhunta sangokwezifiso ngenxa yezindleko zabo eziphezulu. Izinga lokushisa elifanelekile nomswakama ligcinwa ukuze kuqinisekiswe isikhathi eside kunazo zonke sokubumba ngasinye sokwenza ngokwezifiso. Izikhunta ezingokwezifiso, ezinjengalezo ezisetshenziselwa ukubumba injekishini yenjoloba, zigcinwa emazingeni okushisa nasendaweni yomswakama ukuvimbela ukubekeka.

Izinto zethuluzi

Ithuluzi lensimbi livame ukusetshenziswa. Insimbi emnene, i-aluminium, i-nickel noma i-epoxy ifanele kuphela imodeli noma ukukhiqizwa okufishane kakhulu. Ama-aluminium anzima anamuhla (ama-alloys angama-7075 nangu-2024) anomklamo ofanele wesikhunta, angenza kalula isikhunta esikwazi ukuphila impilo eyizi-100,000 noma ngaphezulu ngokulungiswa kwesikhunta esifanele.

Imishini

Izinduna zakhiwa ngezindlela ezimbili eziyinhloko: imishini ejwayelekile ne-EDM. Imishini ejwayelekile, ngendlela yayo evamile, ibiyindlela yomlando yokwakha isikhunta sokulimala. Ngokuthuthuka kwezobuchwepheshe, imishini ye-CNC yaba yindlela esezingeni eliphakeme yokwenza isikhunta esiyinkimbinkimbi esinemininingwane eningi kakhudlwana yokubumba ngesikhathi esingaphansi kunezindlela zendabuko.

Inqubo yokuphehla ugesi kagesi (i-EDM) noma inqubo yokuguguleka kwenhlabathi isetshenziswe kabanzi ekwenzeni isikhunta. Kanye nokuvumela ukwakheka kwezimo okunzima ukuzishintsha, inqubo ivumela ukubumba okwenziwe ngaphambi kokuqina ukuze kwakhiwe ukuze kungabikho ukwelashwa okushisa okudingekayo. Izinguquko ekubumbeni ezenziwe lukhuni ngokugaya okuvamile nokugaya imishini ngokuvamile zidinga ukufaka amandla ukuthambisa isikhunta, kulandele ukuphathwa ukushisa ukuze kuqiniswe futhi. I-EDM inqubo elula lapho i-electrode ebunjiwe, imvamisa eyenziwe ngethusi noma i-graphite, yehliselwa kancane kancane endaweni yokubumba (ngaphezulu kwamahora amaningi), efakwa ku-oyela weparafini (iparafini). Amandla kagesi asetshenziswa phakathi kwethuluzi nokubumba kubangela ukuguguleka kwenhlabathi yendawo yokubumbeka ngendlela engafani ye-electrode.

Cost

Inombolo yemikhonto efakwe kwisikhunta izosebenzisa ngokuqondile ezindlekweni zokubumba. Izicucu ezimbalwa zimbalwa zidinga umsebenzi omncane kakhulu wokusebenzisa, ngakho-ke ukunciphisa inani lamabhokisi ajikelezayo kuzophumela ezindlekweni zokuqala zokwakha zokwakha isikhunta.

Njengoba inani lezimbotshana lidlala indima ebalulekile ezindlekweni zokubumba, kanjalo nobunzima bomklamo wengxenye. Ukuxakaniseka kungafakwa ezintweni eziningi njengokuqedelwa komhlaba, izidingo zokubekezelelana, imicu yangaphakathi noma yangaphandle, imininingwane emihle noma inani lezinto zokudla ezingafakwa.

Imininingwane engaphezulu njengokufakwelwa okungaphansi, noma noma yisiphi isici esibangela ukusetshenziselwa okwengeziwe kuzokhulisa izindleko zokubumba. Ukuqedwa kobubanzi kanye nobuningi bezikhunta kuzobuye kuthonye izindleko.

Inqubo yokubumba injekishini yenjoloba ikhiqiza isivuno esikhulu semikhiqizo ehlala iqinile, ikwenze kube yindlela ephumelelayo futhi ebiza kakhulu yokubumba. Izinqubo ezihlanganayo ze-vulcanization ezibandakanya ukulawulwa kokushisa okunembile zinciphisa kakhulu konke ukungcola.

Inqubo yokufaka

Ngomjovo womjovo, ipulasitiki ebunjiwe idliswa ngenqama ephoqelekile kusuka e-hopper iye emgqonyeni ofudumele. Lapho amagalari edonswa kancane kancane ngumphangi wohlobo lwe-screw, ipulasitiki iyaphoqelelwa ukuba igumbi elifudumele, lapho liyoncibilika. Lapho i-plunger iqhubekela phambili, ipulasitiki encibilikisiwe iyaphoqelelwa ngokusebenzisa i-nozzle esekela ukumelana nesikhunta, iwuvumele ukuba ungene ngaphakathi kwesikhunta sesango kanye nesistimu yomgijimi. Ukubumba kuhlala kubanda ngakho ipulasitiki iyaqina cishe lapho nje isikhunta sigcwalisiwe.

Umjikelezo wokubumba injekishini

Ukulandelana kwemicimbi ngesikhathi sokulimala kwenalithi yengxenye yepulasitiki ibizwa ngokuthi umjikelezo wokubumba umjovo. Umjikelezo uqala lapho isikhunta sivala, silandelwe ngomjovo we-polymer ungene esikhungweni sobumba. Lapho umgodla usugcwalisiwe, ingcindezi yokubamba inakekelwa ukuze inxephezele ukuqina kwento. Esinyathelweni esilandelayo, isikulufa siyajika, sinika isitshudeni esilandelayo isikulufu esingaphambili. Lokhu kubangela ukuthi isikulufu sibuyele emuva njengoba kulungiswa ifishi elilandelayo. Lapho le ngxenye isipholile ngokwanele, isikhunta siyavuleka bese kuthi ingxenye leyo ikhutshwe.

Isayensi yokuqhathanisa nokubumba kwendabuko

Ngokwesiko, ingxenye yomjovo wenqubo yokubumba yenziwa ngcindezelo eyodwa njalo yokugcwalisa nokupakisha umgodi. Le ndlela, noma kunjalo, ivunyelwe ukwehluka okukhulu kubukhulu kusuka kumjikelezo kuya kumjikelezo. Okusetshenziswa kakhulu manje ukubumba okungokwesayensi noma okusikiwe, indlela evulwe yi-RJG Inc. Kulokhu umjovo wepulasitiki "usuliwe" ngezigaba ukuvumela ukulawula okungcono kobukhulu bezingxenye nokuningi komjikelezo-kuya-kumjikelezo (okuvame ukubizwa nge-shot-to -shot embonini) ukungaguquguquki. Okokuqala umgodi ugcwaliswa cishe u-98% ogcwele usebenzisa isilawuli sejubane (isivinini). Yize ingcindezi kufanele yanele ukuvumela ijubane olifunayo, ukulinganiselwa kwengcindezi phakathi nalesi sigaba akufuneki. Lapho umgodi usugcwele u-98%, umshini usuka ekulawuleni isivinini uye ekulawuleni ingcindezi, lapho umgodi "ugcwele khona" ngokucindezela okungaguquki, lapho kudingeka khona isivinini esanele sokufinyelela izingcindezi ezifunwayo. Lokhu kuvumela ubukhulu bezingxenye ukuthi bulawulwe kungakapheli izinkulungwane zamasentimitha noma okungcono.

Izinhlobo ezahlukahlukene zezinqubo zokubumba umjovo

Yize izinqubo eziningi zokubumba umjovo zimbozwa yincazelo yenqubo ejwayelekile ngenhla, kunokuhlukahluka okubalulekile okuningi kokubumba kubandakanya, kepha kungagcini kulokhu:

- die thusi

- Ukubumba injekishini yensimbi

- Ukubumba komjovo omncane

- Ukufakwa kokufakwa kwenjoloba enjoloba engamanzi

Uhlu olubanzi kakhulu lwezinqubo zokubumba umjovo lungatholakala lapha:

Inqubo yokuxazulula inkinga

Njengazo zonke izinqubo zezimboni, ukubumba ngomjovo kungakhiqiza izingxenye ezingenaphutha. Emkhakheni wokubumba ngomjovo, ukuxazulula inkinga kuvame ukwenziwa ngokuhlola izingxenye ezingalunganga ukuthola amaphutha athile futhi kubhekwane nalezi ziphene ngokwakhiwa kwesikhunta noma izici zenqubo uqobo. Izilingo zivame ukwenziwa ngaphambi kokuba umkhiqizo ophelele usebenze emzamweni wokuqagela iziphambeko nokucacisa imininingwane efanelekile yokusebenzisa inqubo yomjovo.

Lapho ugcwalisa isikhunta esisha noma esingajwayelekile okokuqala ngqa, lapho usayizi wesibhamu waleso sikhunta ungaziwa, isethi yezobuchwepheshe / yamathuluzi ingenza isivivinyo ngaphambi kokukhiqizwa okuphelele. Uqala ngesisindo esincane sokudubula bese egcwalisa kancane kancane kuze kube yilapho isikhunta sigcwele ngama-95 kuya kuma-99%. Uma lokhu sekutholakele, kuzosetshenziswa inani elincane lokucindezela ukubamba futhi isikhathi sokubamba sikhuphuke kuze kube yilapho isango limiswa (isikhathi sokuqina) senzekile. Isikhathi sokumisa amasango singanqunywa ngokwandisa isikhathi sokubamba, bese kukalwa ingxenye. Lapho isisindo sengxenye singashintshi, kuyaziwa-ke ukuthi isango selifriziwe futhi akusekho okufakelwa okuthile engxenyeni. Isikhathi sokuqiniswa kwesango sibalulekile, njengoba sinquma isikhathi somjikelezo nekhwalithi nokuvumelana komkhiqizo, nakho uqobo okuyinkinga ebalulekile kwezomnotho kwenqubo yokukhiqiza. Ingcindezi yokubamba yanda kuze kube yilapho izingxenye zingenawo amasinki futhi isisindo sengxenye sitholakele.

Izinkinga zokubumba

Ukubumba komjovo kungubuchwepheshe obuyinkimbinkimbi obunezinkinga zokukhiqiza ezingaba khona. Zingahle zibangelwe yiziphene ekubumbeni, noma kaningi ngenqubo yokubumba ngokwayo.

| Izinkinga zokubumba | Elinye igama | izincazelo | Izimbangela |

|---|---|---|---|

| Blister | Ukuqhakaza | Indawo ekhuphukile noma egqinsiwe engxenyeni engxenye | Ithuluzi noma izinto ezibonakalayo zishisa kakhulu, zivame ukubangelwa ukuntuleka kokupholisa ezungeze ithuluzi noma i-heater enephutha |

| Shisa amamaki | Ukushiswa komoya / ukushiswa kwegesi / udizili | Izindawo ezishisiwe ezimnyama noma onsundu engxenyeni etholakala ezindaweni ezisesitezi kakhulu esangweni noma lapho umoya ubhajwe khona | Ithuluzi alinayo i-venting, ijubane lomjovo liphezulu kakhulu |

| Imisinga yemibala (i-US) | Imisinga yemibala (UK) | Ukuguqulwa okwenziwe endaweni ngombala / kombala | I-Masterbatch ayihlangani kahle, noma impahla isiphelile futhi iqala ukuza njengemvelo kuphela. Izinto zangaphambili ezinemibala "ezihudula" ngombhobho noma nge-valve yokuhlola. |

| Ukudilizwa | Emincane njengezendlalelo ezakhiwe odongeni lwengxenye | Ukungcoliswa kokuqukethwe isib. I-PP exutshwe ne-ABS, kuyingozi kakhulu uma ingxenye isetshenziselwa uhlelo lokuphepha oluphelele njengoba impahla inamandla amancane kakhulu lapho ihlakazwa njengoba izinto zingakwazi ukubopha | |

| Flash | I-Burrs | Izinto ezibonakalayo ezingqekweni ezondile ezidlula ingxenye ejwayelekile yejometri | Ukuqola kugcwele noma kuhlukaniswa umugqa on the ithuluzi konakele, ijubane kakhulu lomjovo / impahla injekiwe, ibutho elinamandla kakhulu liphansi. Kungabuye kubangelwe ukungcola nokungcola okuzungeze indawo yokusebenzisa amathuluzi. |

| Okungcolile okuhlanganisiwe | Imininingwane efakiwe | Izinhlayiya zakwamanye amazwe (izinto ezishisiwe noma ezinye) zigxilisiwe engxenyeni | Izinhlayiya ezingaphezulu kwethuluzi, izinto ezingcolisiwe noma imfucumfucu yangaphandle emgqonyeni, noma ukushisa okukhulu kakhulu kwe-shear okushisa impahla ngaphambi komjovo |

| Amamaki okugeleza | Imigqa yokugeleza | Ngokuqondisa "off tone" imigqa ye-wavy noma amaphethini | Ijubane lokufakwa ekujuleni lihamba kancane (ipulasitiki selehlile kakhulu ngesikhathi sokujova, ijubane lomjovo kufanele libekwe ngokushesha njengoba kufanele inqubo nenqubo esetshenzisiwe) |

| Isango Blush | Izimpawu ze-Halo noma ze-Blush | Iphethini eyindilinga ezungeze isango, imvamisa kuphela impikiswano ekubumbeni komgijimi oshisayo | Ijubane lokufaka lishesha kakhulu, isango / i-sprue / usayizi womgijimi lincane kakhulu, noma i-melt / isikhunta sobumba siphansi kakhulu. |

| Ukujikisa | Ingxenye yonakaliswe ukuhamba kweziyaluyalu kwezinto. | Umklamo wamathuluzi ampofu, isikhundla sesango noma umgijimi. Ijubane lokufaka lifakwe kakhulu. Umklamo omubi wamasango abangela ukuba kufe okuncane kakhulu futhi kudaleke imiphumela. | |

| Imigqa ye-Knit | Imigqa ye-Weld | Imigqa emincane eseceleni engemuva kwezikhonkwane eziyisisekelo noma ngamafasitela ezingxenyeni ezibukeka njengemigqa nje. | Kubangelwa ukuncibilika phambi kwento ezungeze into emi ngokuziqhenya engxenyeni yepulasitiki futhi ekugcineni kokugcwalisa lapho i-melt-front ihlangana khona futhi. Kungancishiswa noma kuqedwe ngocwaningo lokugeleza kokubumba lapho isikhunta esigabeni sokuklanywa. Lapho isikhunta sesenziwe futhi isango selibekiwe, umuntu anganciphisa lolu phutha kuphela ngokushintsha ukunyibilika nokushisa kwesikhunta. |

| Ukucekelwa phansi kwePolymer | Ukuqhekeka kwe-Polymer kusuka ku-hydrose, i-oxidation njll. | Amanzi amaningi emigodini, amazinga okushisa ngokweqile emgqonyeni, isivinini esikhulu sesikulufa okubangelwa ukushisa okukhulu kwe-shear, impahla evunyelwe ukuthi ihlale emgqonyeni isikhathi eside kakhulu, kubhalwa kabusha okuningi kakhulu okusetshenziswayo. | |

| Amamaki wokuswayipha | [uyacwila] | Ukudangala okwenziwe endaweni (Ezindaweni ezinkulu) | Ukubamba isikhathi / ingcindezi iphansi kakhulu, isikhathi sokupholisa sifushane kakhulu, kubagijimi abashisayo abangenalutho lokhu kungadalwa nokushisa kwesango kubekwe phezulu kakhulu. Izinto ezibonakalayo noma izindonga zikhulu kakhulu. |

| Ukudubula okufushane | Okungagcwalisi noma okufushane | Ngokwengxenye | Ukuntuleka kwezinto, ijubane lomjovo noma ingcindezi ephansi kakhulu, isikhunta sibanda kakhulu, ukuntuleka kwamagesi wegesi |

| Amamaki weslayidi | Umaka we-Splash noma imicu yesiliva | Imvamisa ivela njengemifudlana yesiliva emaphethini wokugeleza, kepha kuye ngohlobo nombala wezinto ezibonakalayo kungamelela njengamabhamuza amancane abangelwa umswakama ovalelekile. | Umswakama entweni, imvamisa lapho izinhlaka ze-hygroscopic zomiswe ngokungafanele. Ukubanjiswa kwegesi ezindaweni “zobambo” ngenxa yejubane lomjovo owedlulele kulezi zindawo. Izinto zishisa kakhulu, noma zigundwa kakhulu. |

| Ubungqabavu | Intambo noma isango elide | Imicu efana nezinsalela kokudluliswa kwesibhamu kwadutshulwa okusha | Ithempelesha yomlomo iphakeme kakhulu. Isango alikaze libe yiqhwa, akukho ukwehla kwesikulufa, akukho ikhefu lesiprue, ukubekwa kabi kwamabhendi e-heater ngaphakathi kwethuluzi. |

| Izikhala | Isikhala esingenalutho ngaphakathi kwengxenye (iphakethe lomoya livame ukusetshenziswa) | Ukuntuleka kwengcindezi (ukubamba ingcindezi kusetshenziselwa ukupakisha ingxenye ngesikhathi sokubamba). Ukugcwalisa ngokushesha okukhulu, ungavumeli imiphetho yengxenye ukuthi isethwe. Futhi isikhunta kungenzeka siphelelwe ukubhaliswa (lapho amahafu amabili engagxili kahle futhi ingxenye yezindonga ayilingani ngokufana). Imininingwane enikeziwe ukuqonda okuvamile, Ukulungiswa: Ukuntuleka kwepakethe (okungabambanga) ingcindezi (ingcindezi yepakethe isetshenziselwa ukupakisha yize kuyingxenye ngesikhathi sokubamba). Ukugcwalisa ngokukhulu ukushesha akubangeli lesi simo, njengoba igebe isinki ebingenandawo yokwenzeka. Ngamanye amagama, njengoba ingxenye inciphisa i-resin ihlukaniswe nayo njengoba kwakungekho i-resin eyanele emgodini. Igebe lingenzeka kunoma iyiphi indawo noma ingxenye ayinqunyelwe ukushuba kepha ukugeleza kwenhlaka nokuqhutshwa kokushisa, kepha kungenzeka kakhulu ukuthi kwenzeke ezindaweni ezijiyile njengezimbambo noma abaphathi. Izimbangela ezingezekile zezikhala azincibiliki echibini lokuncibilika. | |

| Umugqa we-Weld | Umugqa we-Knit / umugqa we-Meld / umugqa wokudlulisa | Umugqa ohlukanisiwe lapho imigqa emibili yokugeleza ihlangana khona | Isikhunta noma ukushisa kwempahla kubekwe phansi kakhulu (okubalulekile kuyabanda lapho kuhlangana, ngakho-ke akubopheki). Isikhathi soguquko phakathi komjovo nokudluliswa (ukupakisha nokubamba) kusesekuseni kakhulu. |

| Ukugoqa | Ukuphikisana | Ingxenye ehlanekezelwe | Ukupholisa kufushane kakhulu, impahla iyashisa kakhulu, ukuntuleka kokupholisa kuzungeze ithuluzi, amazinga okushisa amanzi angalunganga (izingxenye ziguqa ngaphakathi zibheke ohlangothini olushisayo lwethuluzi) Ukuncipha okungalingani phakathi kwezindawo zengxenye |

Izindlela ezinjengokuskena kwezezimboni ze-CT kungasiza ekutholeni la maphutha ngaphandle nangaphakathi.

Ukubekezela

Ukubekezelela okubunjiwe kuyisibonelelo esichaziwe ekuphambukeni ngamapharamitha afana nobukhulu, izinsimbi, imilo, noma ama-engeli, njll .Kwengeza amandla wokubeka ukubekezela kuvame ukuba nomkhawulo omncane nobukhulu obukhulu obukhulu, kususelwa kwinqubo esetshenzisiwe. Umjovo wokubumba ujwayelekile uyakwazi ukubekezelela okulingana ne-IT Grade engaba ngu-9-14. Ukubekezelelana okungenzeka kwe-thermoplastic noma i-thermoset ngu- ± 0.200 kuya ku- ± 0.500 millimeters. Kuzicelo ezikhethekile ukubekezelelana okuphansi njengo- ± 5 µm kuwo womabili amadayimitha nezimpawu zomugqa kuyatholakala ekukhiqizeni ngobuningi. Ukuqedwa komhlaba okungu-0.0500 kuya ku-0.1000 µm noma okungcono kungatholakala. Izindawo ezirhabaxa noma ezinamatshe amancane zingenzeka.

| Uhlobo Lokubumba | Ngokuvamile [mm] | Kungenzeka [mm] |

|---|---|---|

| I-Thermoplastic | ± 0.500 | ± 0.200 |

| I-Thermoset | ± 0.500 | ± 0.200 |

Izidingo zamandla

Amandla adingekayo kule nqubo yokubumba umjovo kuya ngezinto eziningi futhi ahluka phakathi kwezinto ezisetshenziswayo. Umhlahlandlela Wenkomba Yezinkomba Zokukhiqiza ithi izidingo zamandla kagesi zixhomeke “ekudonseni kwezinto ezithile, lapho incibilika khona, ekushiseni okushisayo, usayizi wengxenye, nezinga lokubumba.” Ngezansi kwetafula elivela ekhasini 243 lesethenjwa esifanayo njengoba kushiwo ngaphambili elikhombisa kahle kakhulu izici ezihambisana namandla adingekayo ezintweni ezisetshenziswa kakhulu.

| Material | Ukuvuthwa okucacile | Indawo yokuncibilika (° F) | Iphuzu lokuxuba (° C) |

|---|---|---|---|

| I-Epoxy | 1.12 ukuze 1.24 | 248 | 120 |

| I-Phenolic | 1.34 ukuze 1.95 | 248 | 120 |

| Inayiloni | 1.01 ukuze 1.15 | 381 ukuze 509 | 194 ukuze 265 |

| polyethylene | 0.91 ukuze 0.965 | 230 ukuze 243 | 110 ukuze 117 |

| I-Polystyrene | 1.04 ukuze 1.07 | 338 | 170 |

Ukubumba okwenziwe ngamarobhothi

I-automation isho ukuthi usayizi omncane wezingxenye uvumela uhlelo lokuhlola iselula ukuhlola izingxenye eziningi ngokushesha okukhulu. Ngaphezu kwezinhlelo ezikhulayo zokuhlola kumadivaysi othomathikhi, amarobhothi e-axis amaningi angasusa izingxenye kusikhunta futhi azibeke ngezinqubo ezengeziwe.

Izimo ezicacisiwe zifaka ukukhishwa kwezingxenye kusuka kubunji lapho nje lezo zingxenye sezakhiwe, kanye nezinhlelo zokusebenza kombono womshini. Irobhothi ligxila engxenyeni ngemuva kokunwetshwa kwezikhonkwane ze-ejector ukukhulula ingxenye yayo ekubumbeni. Ibese ibenza baba yindawo yokubamba noma ngqo ohlelweni lokuhlola. Ukuzikhethela kuncike kuhlobo lomkhiqizo, kanye nokwakheka okuvamile kwemishini yokukhiqiza. Izinhlelo zokubuka ezifakwe emarobhothi zithuthukise kakhulu ukulawulwa kwekhwalithi kwezingxenye ezibunjiwe. Irobhothi eliselula linganquma ngokunembile ukunemba kokubekwa kwengxenye yensimbi, futhi lihlolwe ngokushesha kunokuba umuntu akwazi.